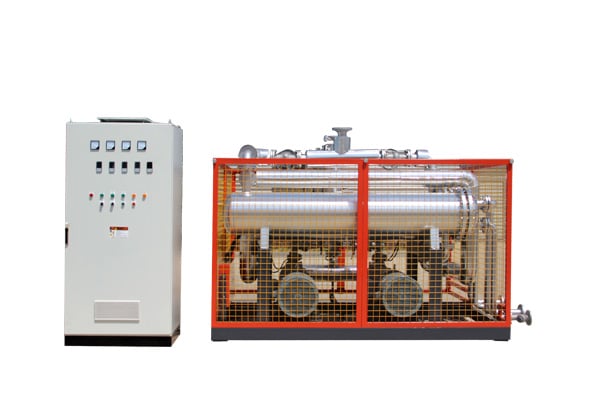

Heat transfer oil electric heaters https://8ruiyan.com/en/all-organic-heat-carrier-boilers/ are widely used in industrial production to provide stable heat sources for manufacturing equipment. Given their working principles and structural characteristics, maintenance is crucial as it directly impacts the equipment’s service life, operational efficiency, and safety. Below is a detailed guide on proper maintenance procedures.

I. Routine Maintenance

- Regularly Inspect Heat Transfer Oil Quality

- Heat transfer oil is the core medium; its quality affects performance.

- Periodically test viscosity, acid value, flash point, and other indicators.

- Replace degraded, oxidized, or contaminated oil promptly to prevent efficiency loss or safety hazards.

- Check Heating Elements and Electrical Control System

- Inspect heating elements for carbon buildup, scaling, or damage. Clean surfaces if fouled.

- Ensure electrical connections are secure and components function properly.

- Inspect Circulation Pump and Piping

- Verify the pump operates smoothly without leaks or abnormal noise.

- Check pipelines for blockages, leaks, or corrosion. Address issues immediately.

- Clean Equipment Surface and Radiators

- Remove accumulated dust and debris to maintain ventilation.

- Prevent overheating caused by poor heat dissipation.

II. Scheduled Maintenance

- Replace Heat Transfer Oil

- Oil degrades over time. Replace it based on usage and test results.

- Flush the system thoroughly before adding new oil to avoid contamination.

- Test Insulation Performance of Heating Elements

- Measure insulation resistance with a megohmmeter.

- Replace elements if insulation fails to prevent electrical faults.

- Calibrate Temperature Control System

- Ensure temperature readings match actual values.

- Adjust or replace sensors if deviations occur.

- Inspect Safety Valve and Pressure Gauge

- Confirm the safety valve activates at the set pressure.

- Verify pressure gauge accuracy to ensure safe operation.

III. Troubleshooting and Prevention

- Heating Element Failure

- Stop operation immediately and replace damaged elements.

- Use compatible specifications during replacement.

- Heat Transfer Oil Leakage

- Shut down the system, locate leaks, and repair them.

- Recheck seals after repair.

- Equipment Overheating

- Causes include poor oil circulation, scaled elements, or blocked radiators.

- Diagnose and resolve the root issue before restarting.

- Electrical Faults

- For tripping or leakage, inspect wiring, components, and insulation.

- Rectify faults before resuming operation.

IV. Key Precautions

- Strictly follow operating procedures to avoid damage or accidents.

- Train operators regularly on maintenance and emergency response.

- Keep surroundings clean and free of obstructions; ensure firefighting equipment is accessible.

- Schedule professional inspections periodically for comprehensive assessment.

Závěr

Proper maintenance of heat transfer oil electric heaters is essential for safe, efficient, and long-lasting operation. Through routine checks, scheduled servicing, and proactive troubleshooting, equipment lifespan and productivity can be maximized while minimizing downtime. Operators must be well-trained and adhere strictly to protocols to ensure operational safety.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com