Biphenyl furnace has become an indispensable heating equipment in many industrial fields due to its efficient and stable heat transfer performance. In this article, we will discuss the use of biphenyl furnaces and their application scenarios in different industries to help customers fully understand the applicability of biphenyl furnaces.

Main uses of biphenyl furnaces

The core feature of the biphenyl furnace is its excellent high-temperature conductivity, which enables a stable output of ultra-high temperatures and makes it suitable for industrial processes with stringent temperature requirements and where the heating process needs to be continuous and stable. Biphenyl furnaces are usually used to heat fluid media with high heat and good flowability to meet the heat requirements of the production process.

Applicable industries

- petrochemical industry

In the petrochemical industry, many processes require constant high temperature heating to ensure efficient chemical reactions. Biphenyl furnaces provide a stable high temperature output and are suitable for applications such as heavy oil and bitumen heating as well as pipeline heating. Its efficient heat transfer performance meets the dual requirements of petrochemical companies for temperature control and safety. - pharmaceutical industry

Pharmaceutical production often involves high temperature processes such as distillation and concentration of liquid media. The precise temperature control and high thermal efficiency of the biphenyl furnace enables fine heating of the raw materials, thus guaranteeing the quality and purity of the drug production. In addition, the closed loop system design of the biphenyl furnace helps to avoid the entry of external contaminants and meets the strict requirements of the pharmaceutical industry for equipment cleanliness and hygiene standards. - Chemical industry

Various production processes in the chemical industry, such as organic synthesis and catalytic reaction, require high temperature conditions to maintain the activity of chemical reaction. The biphenyl furnace provides a stable high temperature environment for the chemical industry, and can maintain a uniform temperature inside the equipment, avoiding poor reaction results due to temperature fluctuations, which helps to improve the qualification rate and production efficiency of chemical products. - Food processing industry

In the field of food processing, biphenyl ovens are mainly used in some processes that require high temperature sterilisation or treatment. For example, certain ingredients in food products need to be treated at high temperatures to remove bacteria or to achieve a predetermined processing effect. The stable high temperatures provided by biphenyl ovens can effectively maintain the heating effect of the product while meeting the hygiene and safety requirements of the food industry. - Textile printing and dyeing industry

The textile printing and dyeing industry has high requirements for heating equipment, especially in the dyeing and fixing process where high temperatures need to be sustained to ensure the colour and dimensional stability of the textiles. The high temperature control capability and heat transfer efficiency of biphenyl furnaces can meet these demands, enabling better penetration of dyes into fabrics and enhancing the uniformity and durability of dyeing results. - paper industry

In the papermaking process, a large amount of heat is required for the drying and treatment of pulp. The biphenyl furnace provides a stable high-temperature heat source, which can effectively promote the drying of pulp, improve production efficiency and ensure the flatness and quality of paper.

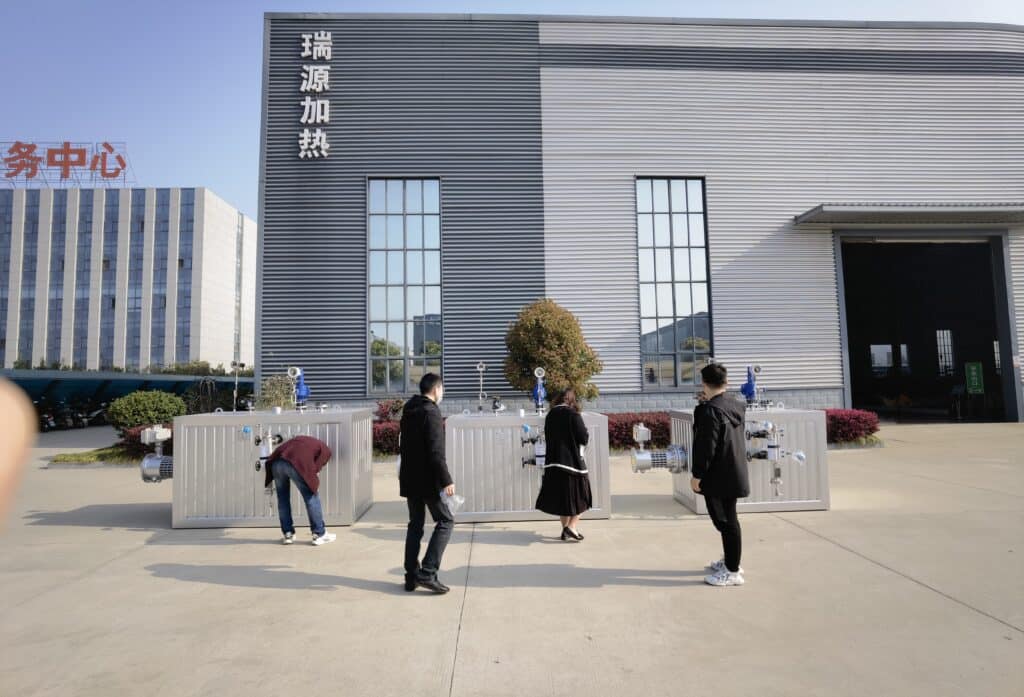

Biphenyl Furnace Solution of Jiangsu Ruiyuan Heating Equipment Technology Co.

Jiangsu Ruiyuan Heating Equipment Technology Co., Ltd. is committed to providing high quality biphenyl furnace equipment for various industries. Our biphenyl furnace is made of high-performance materials with excellent high-temperature control, suitable for a variety of industrial heating needs. We can also carry out non-standard customisation according to customers' special needs to ensure that the equipment perfectly matches the specific application scenarios.

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading: