In industrial production, biphenyl furnace is widely used as a kind of high-efficiency heating equipment in industries with high temperature demand. However, different production conditions require different models of biphenyl furnace to ensure the best heating effect and production efficiency. In this article, we will introduce the key elements that should be considered when choosing the right model of biphenyl furnace in detail to help enterprises make a reasonable choice.

1. Determination of heating requirements

Production process requirements When choosing the model of biphenyl furnace, the first step is to clarify its application requirements in the production process, such as the production temperature range, heating speed and continuous working time. Different processes have different requirements for heating equipment, ensuring that the temperature performance of the biphenyl furnace matches the production process is the first step in the selection process.

Material Characteristics The type of material to be heated in the production process will also affect the selection of biphenyl furnace. Different materials have different heat transfer efficiency and thermal stability, so it is necessary to consider the heat transfer method of the equipment and its compatibility with the material properties to obtain the best heating effect.

2. Temperature control capability

Temperature control accuracy The temperature control accuracy of biphenyl furnace is a key factor in determining the heating effect. Generally speaking, high-precision temperature control systems are more suitable for production processes that are sensitive to temperature fluctuations, and can stabilise the output of a specific temperature to ensure stable product quality.

Maximum temperature and temperature control range The maximum temperature and temperature control range of the biphenyl furnace are also elements to be concerned about when selecting the model. When selecting, you should choose the temperature control range that meets the production requirements to ensure that the working condition of the equipment is still stable when the temperature required for production is reached.

3. Consideration of energy-saving performance of equipment

Energy efficiency of equipment In long-term production, the energy efficiency of the equipment directly affects the operating costs. Choosing a biphenyl furnace with high energy efficiency not only reduces energy consumption, but also reduces the heat loss of the equipment. Efficient insulation materials and energy-saving design can effectively improve the overall energy efficiency of the equipment, which helps to control production costs.

Power Adjustment Function Biphenyl furnaces with power regulation are able to adjust the power according to the heating demand, reducing unnecessary energy consumption. This is particularly important for processes with fluctuating heating requirements and helps to optimise energy efficiency in plant operation.

4. Understanding safety features and service life

Equipment Safety Performance Safety is one of the key factors in choosing biphenyl furnace, especially for high temperature operation environment, choosing the equipment with perfect safety protection measures can effectively reduce the production risk. When choosing the equipment, you should check whether the equipment has overheating protection, leakage protection and other functions to ensure the safety of use.

Service life and maintenance High-quality biphenyl furnace equipment usually has a long service life and is relatively easy to maintain. Choosing a biphenyl furnace that has a long service life and is resistant to wear and tear reduces maintenance costs and improves productivity.

5. Branding and after-sales service

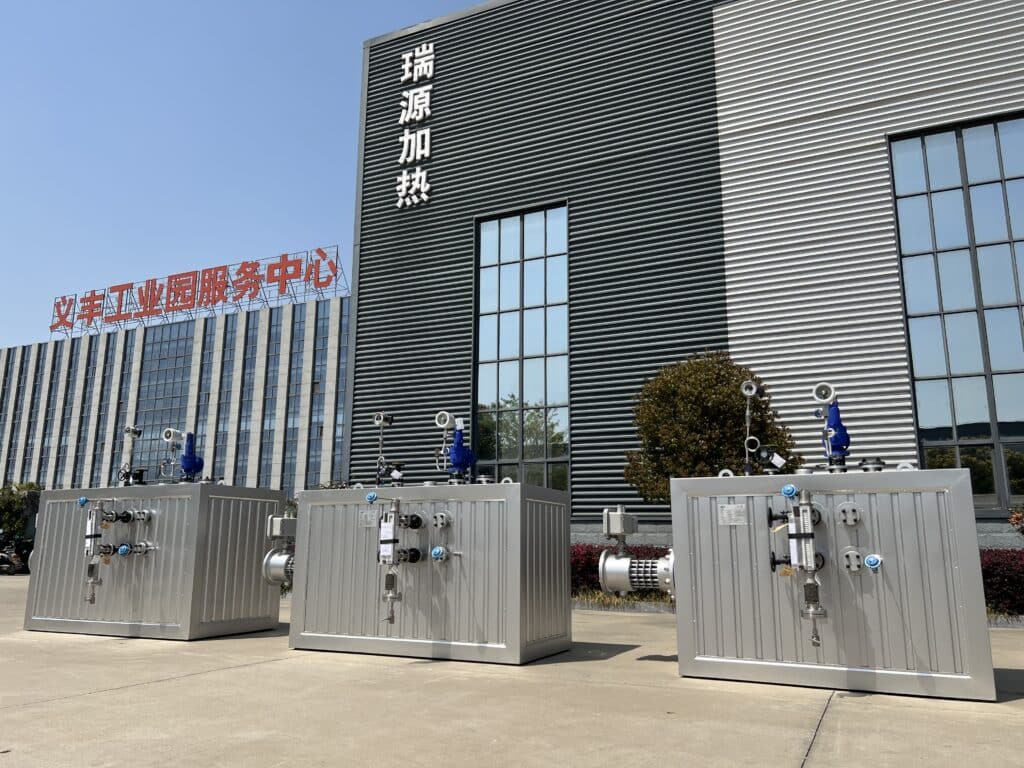

brand reputation The brand reflects the quality and stability of the equipment to a certain extent, and choosing a brand with a good reputation can improve the reliability of the purchase. Jiangsu Ruiyuan Heating Equipment Technology Co., Ltd. as a professional manufacturer of biphenyl furnace in the industry, provides high-quality products, and can be customised according to customer needs for non-standard.

After-sales service support Good after-sales service can provide protection for the installation and commissioning, routine maintenance of the equipment. When choosing biphenyl furnace, it is recommended to choose the brand with perfect after-sales service system to ensure the technical support during the operation of the equipment.

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading: