Industrial oven is widely used in modern production, and its main function is to heat, dry or heat treatment of materials. In order to achieve the ideal heating effect, the oven needs to have uniform temperature distribution and accurate temperature control. Jiangsu Ruiyuan Heating Equipment Technology Co., Ltd. focuses on the production and research and development of industrial ovens, and provides many types of customised ovens, which are suitable for a variety of industrial heating needs.

1. Heating principle of the oven

The core of the industrial oven is to make the internal air temperature reach the set value and keep it in a stable range through different heating methods. The main heating methods include:

1.1 Hot air circulation heating Hot air circulation is the most common heating method in ovens. Heating elements (such as electric heating tubes) are installed inside the oven, and when the electric heating tubes generate heat, a fan blows the hot air evenly to the inside of the oven. This method can effectively maintain the temperature uniformity inside the oven and is suitable for materials that require uniform heating. The hot air circulation system not only improves the drying speed, but also further enhances the uniformity of heat distribution by circulating the fan.

1.2 Infrared heating The heating element of the infrared oven will emit infrared rays, which will act directly on the surface of the material through radiation and heat up quickly in a short time. This method is suitable for materials with fast heating speed and high temperature requirements. Infrared heating is more efficient than traditional hot air circulation, which can reduce energy consumption, and it is also suitable for industrial production with high requirements on drying speed.

1.3 Electric and gas heating Electric and gas heating are common sources of energy for ovens. Electric heating ovens have a higher precision of temperature control and are suitable for precision production processes, while gas heating is relatively low-cost and is suitable for industrial production with larger outputs. Electric heating provides heat through resistance wires or electric heating tubes, while gas heating provides heat directly through burners.

2. Principle of thermostatic control of the oven

In order to ensure that the temperature inside the oven meets the process requirements, the thermostatic control system is crucial. The temperature control system of the oven mainly includes the following parts:

2.1 Temperature sensors Temperature sensors are installed at various locations inside the oven to monitor the temperature inside the oven in real time. The sensors transmit the detected temperature signals to the control system, which regulates the power of the heating elements through accurate temperature feedback to maintain a stable temperature inside the oven.

2.2 PID control system PID control system is a commonly used temperature control technology.PID control system can dynamically adjust the heating intensity according to the deviation between the temperature setting value and the actual temperature value, realising the combination of rapid warming and constant temperature control.PID control can reduce the temperature fluctuation and make the temperature inside the oven more stable, which is suitable for the application of the industry that requires high precision of temperature control.

2.3 Thermal insulation design The box of the oven is usually insulated with heat-insulating materials, such as rock wool and aluminosilicate wool, which can effectively reduce heat loss and ensure that the temperature inside the oven remains constant. Good thermal insulation design helps to reduce energy consumption and improve the thermostatic effect.

3. Oven homogeneous design and temperature distribution

The heating effect of industrial ovens is closely related to temperature uniformity. Temperature uniformity is an important indicator to measure the performance of the oven, especially in the hot air circulation oven, good temperature distribution is the key to ensure product quality.

3.1 Air duct design The air duct design directly affects the circulation effect of the hot air. Reasonable air duct design can make the hot air form a uniform flow in the oven and reduce the temperature difference. This design is suitable for materials that need to be fully heated and can prevent localised temperatures from being too high or too low.

3.2 Multi-point temperature monitoring In order to improve temperature uniformity, some high-end ovens will be equipped with multi-point temperature monitoring system. By setting multiple temperature sensors inside the oven, the temperature of each point is detected in real time, so as to achieve fine temperature control management.

4. Advantages of the oven of Jiangsu Ruiyuan Heating Equipment Technology Co.

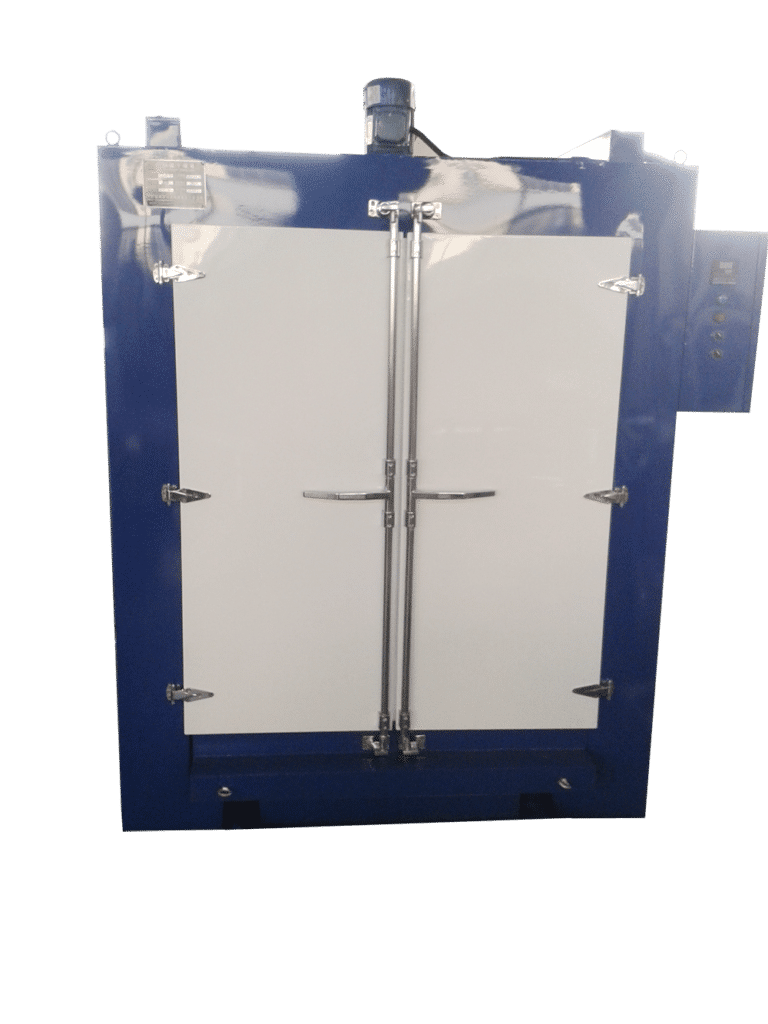

The industrial ovens of Jiangsu Ruiyuan Heating Equipment Technology Co., Ltd. adopt advanced thermostatic control technology and highly efficient heating system, which are suitable for a variety of industrial uses. Our oven products have good thermal insulation and uniform temperature distribution, while they can be customised to meet the special requirements of different production processes.

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading: