Unique advantages of heat transfer oil boilers

Thermal oil boiler is one of the highly efficient thermal energy equipments in industrial production, which is widely used in chemical, pharmaceutical, food processing and other industries. Compared with traditional steam boilers, thermal oil boilers use thermal oil as heat carrier, which can not only work under lower pressure, but also provide a high temperature and stable heat source, which makes many demanding production processes run smoothly.

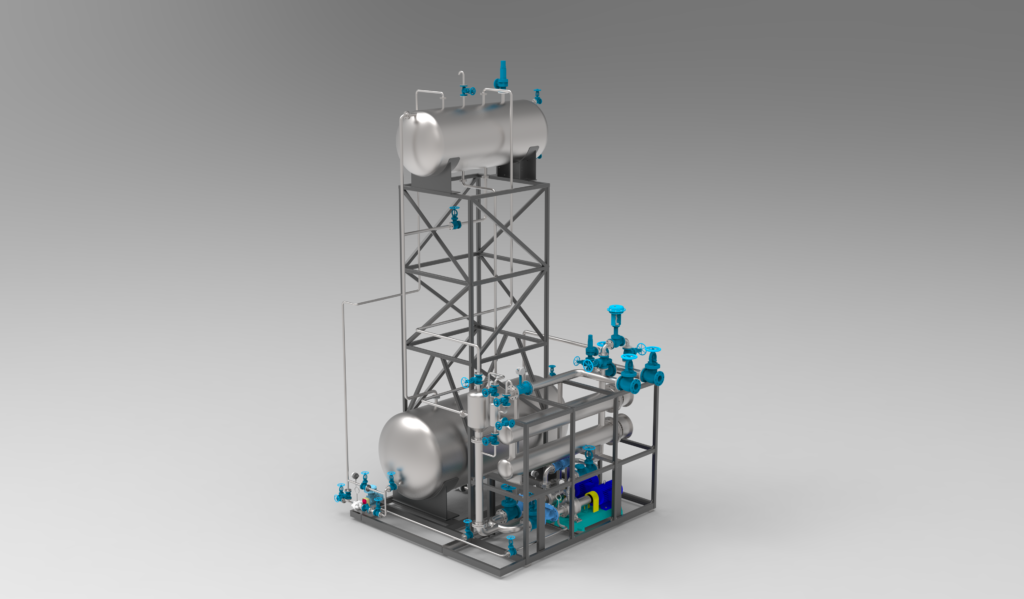

The working principle of heat transfer oil boiler::

A thermal oil boiler heats thermal oil by burning fuel, which transfers heat to the process equipment to be heated. The thermal oil used in this system has good thermal stability and low vapour pressure, allowing the boiler to operate efficiently and safely.

Comparison of heat transfer oil boiler and other boiler equipment

- Differences between steam boilers and thermal oil boilersWhile steam boilers typically need to operate at higher pressures, thermal oil boilers provide a high temperature heat source at lower pressures by utilising the heat transfer properties of thermal oil. Due to their low pressure characteristics, thermal oil boilers are safer than steam boilers and require less maintenance of the equipment.

- Oil-fired steam boiler vs. thermal oil boilerAn oil-fired steam boiler generates steam by heating water with fuel oil, while a thermal oil boiler heats thermal oil with fuel. While both can provide a high-temperature heat source, the thermal oil boiler is superior in efficiency and safety because it operates without generating high-pressure steam, avoiding the risk of steam leaks or explosions.

Key technologies to improve boiler efficiency

Improving boiler efficiency is a goal sought by every industrial organisation. Thermal oil boilers significantly improve their operating efficiency in the following ways:

- Optimisation of the combustion systemOptimisation of the boiler's burner design ensures that the fuel is burned completely. The thermal efficiency of the boiler can be maximised through more precise air supply and temperature control.

- Waste heat recovery systemHeat transfer oil boilers can be equipped with waste heat recovery devices to recycle the heat in the exhaust gas. For example, the heat in the exhaust gas can be used to preheat the feed oil, thereby reducing energy consumption and improving overall efficiency.

- Highly efficient thermal insulation designOptimise the insulation materials and insulation design of the boiler to reduce heat loss and ensure that the heat transfer oil can maintain a high temperature during transmission, further improving the efficiency of the boiler.

- Regular maintenance and overhaulRegularly check the operating condition of the thermal oil boiler, clean the oil tubes and combustion system, remove the accumulated scale and impurities, and ensure that the boiler equipment maintains the best operating condition. Good maintenance not only improves boiler efficiency, but also extends the service life of boiler equipment.

Application areas of heat transfer oil boilers

With its high temperature and high efficiency, heat transfer oil boiler is widely used in many industrial fields. The following are some typical application scenarios:

- Chemical industryChemical production requires a variety of chemical reactions at high temperatures, thermal oil boilers can provide a stable high-temperature heat source to ensure the smooth progress of chemical reactions.

- pharmaceutical industryIn the pharmaceutical industry, many production processes require precise temperature control. Thermal oil boilers can provide a stable and efficient heating system to meet the strict temperature control requirements of the pharmaceutical process and ensure the quality of drugs.

- food processingFood processing requires high-temperature steaming, drying and other processes, thermal oil boilers can provide a stable heat source for these production links to improve production efficiency and maintain the quality of food.

- metal processingIn the metal processing industry, processes such as heat treatment and metal forming often require high temperature heating. Thermal oil boilers can provide the required high temperature heat source to ensure the smooth running of the metal working process.

Jiangsu Ruiyuan's thermal oil boiler solutions

As an industry-leading boiler equipment manufacturer, Jiangsu Ruiyuan Heating Equipment Technology Co., Ltd. provides customised thermal oil boiler solutions for all types of industrial customers. We are committed to providing customers with efficient and energy-saving thermal energy equipment to help companies improve productivity and reduce operating costs.

Our thermal oil boiler products are subject to strict quality control, with excellent performance and safety, and are widely used in many industries, such as chemical, pharmaceutical, food and so on. Both the high-efficiency combustion system and advanced waste heat recovery technology ensure the high efficiency and long-term stable operation of thermal oil boilers.

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading: