As an important equipment for industrial and civil heating, the thermal efficiency and energy-saving performance of boilers is always a core concern in selection and operation optimisation. High-efficiency boilers not only reduce fuel costs, but also reduce environmental pollution, in line with the requirements of modern industry for a low-carbon economy. So, what is boiler thermal efficiency? How to evaluate whether it is energy efficient?

What is boiler thermal efficiency?

Boiler thermal efficiency is the ratio of the effective heat output of the boiler to the total heat input of the fuel, usually expressed as a percentage. It reflects the degree of utilisation of fuel energy by the boiler and is one of the important indicators of boiler performance.

- equation::

In practice, the thermal efficiency of a boiler is not a constant value and can vary depending on operating conditions, fuel type and equipment design.

Classification of thermal efficiency

Boiler thermal efficiencies are usually divided into the following two categories:

- Rated thermal efficiency::

- It is the value of thermal efficiency measured under standard operating conditions, a parameter provided by the manufacturer and usually used as an important basis for boiler selection.

- Operational thermal efficiency::

- It is the thermal efficiency of the boiler under actual operating conditions. Due to the influence of ambient temperature, fuel quality and other factors, the operating thermal efficiency is generally lower than the rated value.

Factors affecting boiler thermal efficiency

- Fuel type and quality The combustion value and moisture content of different fuels have a significant effect on thermal efficiency. Example:

- Natural gas boilers typically have high thermal efficiencies because they burn well and pollute less.

- Coal boilers may have low efficiency due to high volatiles and incomplete combustion.

- Combustion system design

- The advanced combustion system optimises the mixing ratio of fuel and air, improving combustion efficiency and reducing unburnt losses.

- Heat transfer system performance

- The design and material of the heat exchanger play a key role in the efficiency of heat transfer. A highly efficient heat exchanger converts more of the heat of combustion into useful heat.

- Exhaust heat loss

- High flue gas temperatures are one of the main causes of reduced boiler thermal efficiency. Modern boilers can significantly improve efficiency by using condensing technology to recover flue gas waste heat.

- Operation and maintenance status

- Carbon build-up, scaling, and leaky pipework can all reduce boiler operating efficiency. Regular maintenance is essential.

Criteria for determining whether a boiler is energy efficient

Evaluating whether a boiler is energy efficient requires a combination of the following aspects:

- Thermal efficiency level

- Energy-efficient boilers typically have thermal efficiencies of 901 TP3T or more, while conventional boilers may only be 701 TP3T to 801 TP3T.

- Energy performance

- Fuel consumption per unit of heat output is a direct indicator of the boiler's energy-saving performance.

- Environmental performance

- High-efficiency boilers are usually accompanied by lower pollutant emissions, such as NOx and CO2 emissions.

- running cost

- Energy-efficient boilers can effectively reduce long-term operating costs due to high fuel utilisation.

Strategies for Improving Boiler Thermal Efficiency

- Choosing High Efficiency Boiler Equipment

- Quality boilers are usually equipped with advanced combustion and heat exchange systems to ensure that the fuel burns well.

- Optimisation of operating parameters

- The air excess factor is adjusted to ensure that the fuel reacts fully with the air while avoiding heat loss due to excess air.

- Adoption of waste heat recovery technology

- The use of condensation technology to recover latent heat from exhaust fumes is particularly effective at low temperatures.

- Regular cleaning and maintenance

- Removing carbon and scale and keeping heat exchange surfaces clean can dramatically increase thermal efficiency.

- Upgrade control system

- The use of intelligent control technology enables precise regulation of combustion and heat distribution, reducing unnecessary energy waste.

Advantages of energy efficient boilers

- Cost savings

- High-efficiency boilers can significantly reduce fuel consumption and reduce a company's energy bills.

- Environmental benefits

- Energy-saving boilers burn more fully and emit less, in line with national environmental policies and industry standards.

- Extended equipment life

- Boilers with high thermal efficiency run smoother, reducing wear and tear and ageing of the equipment.

- Productivity Improvement

- In industrial production, a stable heat supply improves process accuracy and product quality.

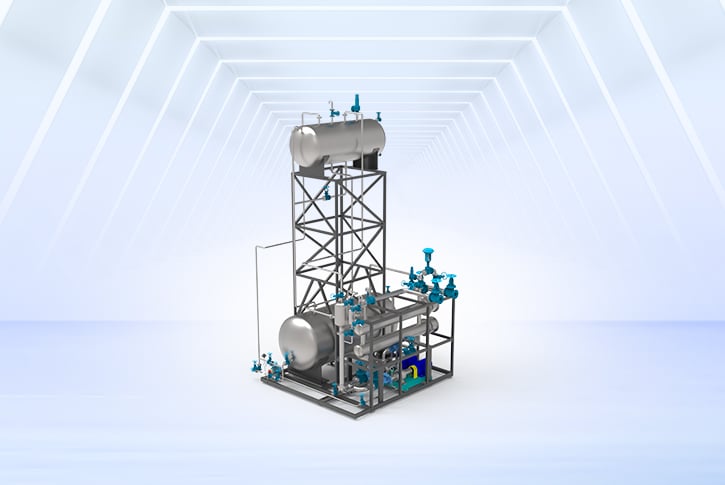

Boiler product advantages of Jiangsu Ruiyuan Heating Equipment Technology Co.

As a leader in the boiler industry, Jiangsu Ruiyuan Heating Equipment Technology Co., Ltd. is committed to researching and developing energy efficient boiler equipment. Our products have the following features:

- advanced technology

- Introduced condensing waste heat recovery technology to increase boiler thermal efficiency to over 95%.

- Personalisation

- Boiler systems are designed according to customer needs to meet the special requirements of a wide range of industrial scenarios.

- green

- All products strictly follow the environmental protection standards to reduce pollutant emissions.

- Intelligent control

- Equipped with high-precision control system, it realises the perfect combination of energy saving and high efficiency.

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading: