Quality first, non-standard customisation

ovens

Products

Working Principle

Power specifications on request

The oven shell is generally made of thin steel plate with baked paint surface, and the studio is made of high quality structural steel plate. The shell and the studio are filled with aluminium silicate fibre. The heater is installed at the bottom, and can also be placed on the top or both sides. The temperature control instrument adopts digital display intelligent table, PID regulation, controller and connected with alarm device. Make the operation of the oven more simple, fast and effective.

Main features

(1) The oven can obtain higher working temperature under lower operating pressure. Heat transfer oil liquid phase transport heat in the pipeline to 2.3 ~ 2.7m / s flow in <300 ° C when the saturated vapour pressure of water 1 / (70 ~ 80), security. The oil temperature can be as high as 320°C, therefore. The super-temperature and high-pressure water vapour can only supply heat for topcoat drying, and the pipelines, valves, radiators, etc. must also withstand high pressure;.

(2) The oven can obtain higher working temperature under lower operating pressure. Heat transfer oil liquid phase transport heat in the pipeline to 2.3 ~ 2.7m / s flow in <300 ° C when the saturated vapour pressure of water 1 / (70 ~ 80), good safety. The oil temperature can be as high as 320°C, therefore. The super-temperature and high-pressure water vapour can only supply heat for topcoat drying, and the pipelines, valves, radiators, etc. must also withstand high pressure;.

(3) The oven can carry out stable heating and more accurate temperature regulation. Due to the heating system oil volume can be up to 3t and the oil specific heat is relatively large, the oil temperature is not easy to drastic change, the temperature is easier to control. The oil temperature can be controlled at ±1℃.

(4) The oven has complete operation control and safety monitoring devices.

(5) oven and water boiler, compared with water, does not consume water, do not need special water treatment equipment, winter also do not need to gap to the pipeline heating in order to prevent freezing, and do not need to be manned, reducing the operating costs.

(6) The oven has high thermal efficiency and good economy. Heat utilisation is 40%~50% higher than steam.

Comparison of electrically heated thermal oil oven with other heating methods

1. Electric heating.√

Low cost, simple operation, suitable for small-scale use

2. Compared with traditional water boilers, no water consumption√

Thermal oil heating oven does not consume water, do not need special water treatment equipment, winter also do not need to gap to the pipeline heating to prevent freezing, in addition to its high thermal efficiency, so that the heating oven of the input-output ratio is relatively high.

3. Stable heating and more precise temperature regulation√

As the heating system oil volume can be up to 3t, and the oil specific heat is relatively large, the oil temperature is not easy to change dramatically, the temperature is easier to control. The oil temperature can be controlled at ±1℃. The heating speed of the drying room is also faster and the temperature is more stable.

3. Easy to operate safe operation√

Thermal oil heating oven has complete operation control and safety monitoring devices, which on the one hand facilitates the practical operation of the relevant operators, and on the other hand increases the safety coefficient of enterprise production.

Product Showcase

specificities

Wide range of applications

01

Chemical industry

02

Plastics/Rubber Industry

03

Textile printing and dyeing industry

03

Wood processing industry

Product Advantage

Quality first

quality control

We choose high quality materials and produce them in strict accordance with quality standards.

quality control

rigorous standard

Equipped with the Special Inspection Institute on-site personnel, the equipment factory have been strictly inspected.

Expertise

Precision and Meticulousness

Rigorous welding, precision and meticulous, seamless welding, fine workmanship and exquisite.

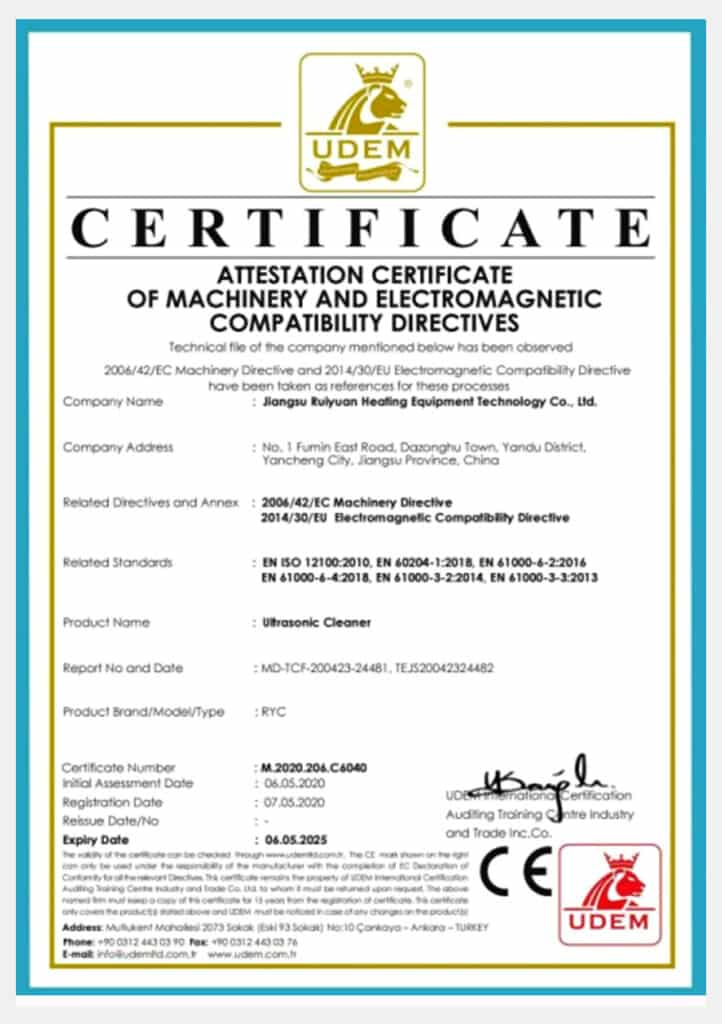

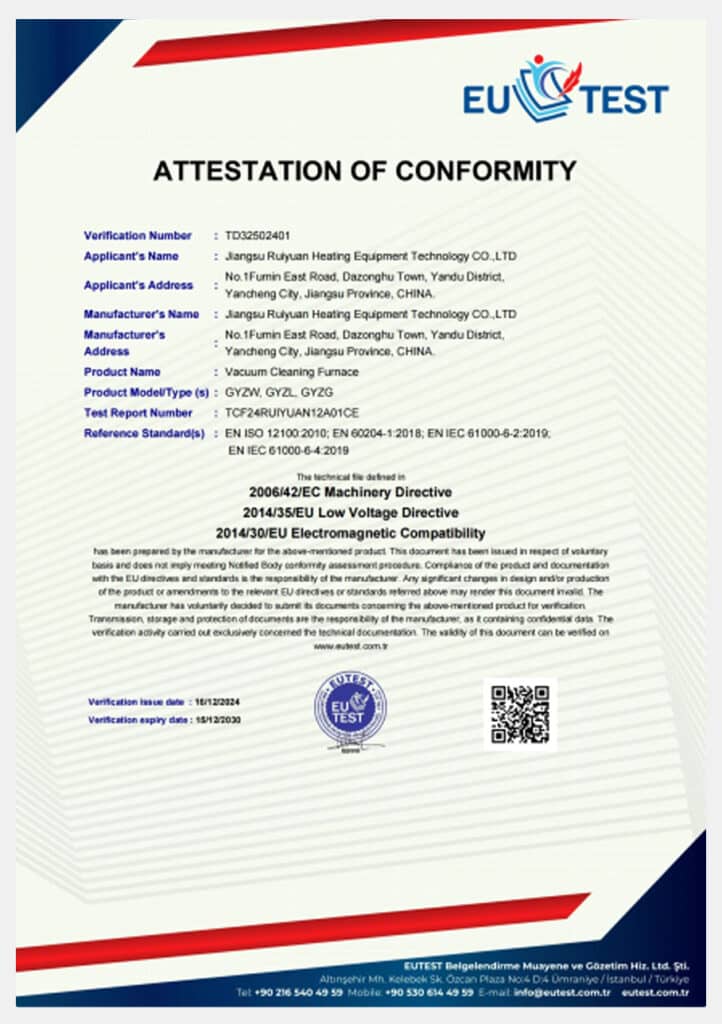

Complete qualification, reliable quality