I. Introduction

Industrial automation, energy conservation, and the need for efficient heat transfer are growing. Industrial air heaters https://8ruiyan.com/en/all-air-heaters/ are increasingly vital across many industries. They serve as the core “heat source” in systems like drying, hot air circulation, combustion support, heating furnaces, and environmental control. Air heaters convert electricity, steam, thermal oil, or fuel into heat. This rapidly warms air, providing crucial temperature support for industrial processes.

This article explains air heater principles, structure, types, performance parameters, and applications. It aims to give readers a thorough understanding of this key equipment.

II. Working Principle

Air heaters operate on a basic principle:

- Internal heating elements convert energy into heat. Elements include electric tubes, finned tubes, or burners.

- This heat transfers to air. Transfer happens via thermal convection or forced airflow.

- The air reaches a set temperature. This allows precise control of the air stream.

The heater body usually connects to fans, ducts, and control systems. During operation:

- A fan pushes air into the heater body.

- Air flows around the heating elements, absorbing heat.

- The heated air then moves to the process endpoint.

III. Main Classifications

Air heaters are categorized by heat source, structure, and environment:

- By Heat Source:

- Electric: Use electric tubes (electric → heat). Ideal for clean rooms needing precise control.

- Gas-Fired: Burn gas (natural gas, LPG) to create heat. Best for large hot air systems.

- Steam/Thermal Oil: Use indirect heating. Suited for high-temp, high-humidity, or explosive areas.

- Heat Pump: Use heat pump systems. Energy-efficient and eco-friendly. Good for medium-low temps.

- By Structure:

- Finned Tube: For low air speed and large heat exchange areas.

- High-Temp Cylindrical: For high heat with low airflow (over 850°C possible).

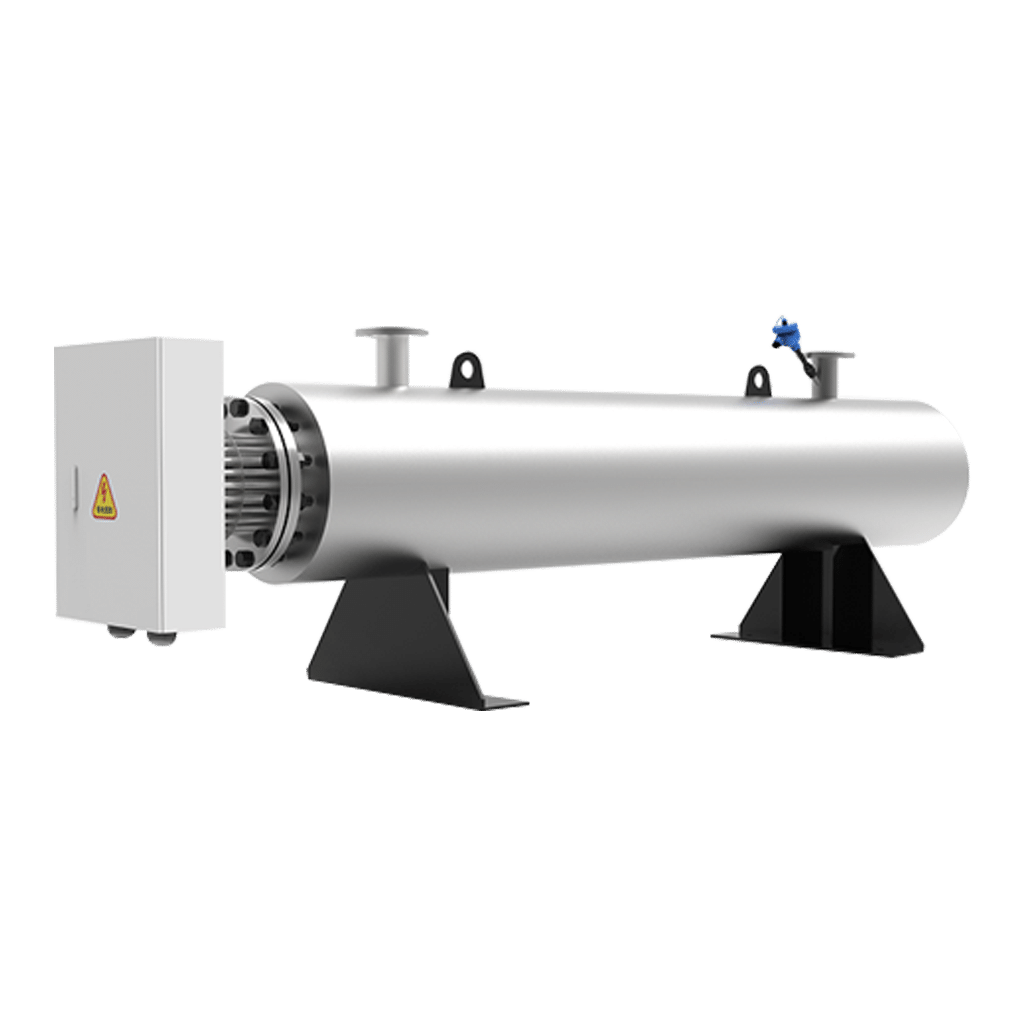

- Shell-and-Tube: For high-pressure, closed-loop systems.

- By Air Supply:

- Natural Convection: No fan. Relies on natural air movement.

- Forced Air: Uses a fan. Improves heat exchange efficiency.

IV. Technical Structure Details

Key components determine heater efficiency and stability:

- Heating Elements:

- Common types: U-shaped electric tubes, finned tubes, ceramic rods.

- Materials: Usually 304/316 stainless steel (corrosion-resistant, heat-tolerant).

- Option: Explosion-proof versions for flammable gas areas.

- Heat Exchange Chamber:

- Outer shell: Carbon steel or stainless steel, with insulation.

- Internal design: Streamlined air channels for even heat spread.

- Access: Maintenance ports for easy service.

- Control System:

- Includes: Thermocouples/RTDs, PID controllers, SSR modules.

- Functions: Constant temp control, over-temp alarms, timers, safety interlocks.

- Option: PLC remote control for smart management.

- Insulation & Sealing:

- Insulation: Materials like aluminum silicate wool, rock wool, aerogel.

- Cladding: Aluminum or stainless steel outer layer (improves protection).

- Seals: High-temperature gaskets at flanges (prevents leaks).

V. Key Technical Parameters

| Parameter | Range/Description |

|---|---|

| Heating Power | 3kW ~ 2000kW (customizable) |

| Operating Temp | Ambient ~ 850°C (High-temp: up to 1000°C) |

| Air Flow | 50m³/h ~ 50,000m³/h |

| Voltage | AC220V/380V/660V/3-Phase 5-Wire |

| Temp Control Accur. | ±1℃ ~ ±5℃ (PID control) |

| Materials | Q235, 304, 316L, Titanium, Explosion-proof coating |

VI. Application Areas

Air heaters are used widely:

- Spraying/Drying: Auto paint lines, metal treatment.

- Plastics Processing: Film/pipe preheating for extruders.

- Pharmaceuticals: Clean air circulation, sterilization.

- Chemicals: Reaction atmosphere heating, pipe tracing.

- Food Processing: Drying, dehydration.

- Energy/Power: Air preheating, flue gas reheat (SCR).

VII. Advantages & Trends

Key Advantages:

- Fast heating, high efficiency.

- Precise temperature control.

- Compact design, easy to install/maintain.

- High safety (multiple protections).

- Suited for continuous operation, adaptable.

Development Trends:

- Higher temperatures, smarter controls.

- Modular design (easier expansion/repair).

- Remote monitoring & IoT integration (improves efficiency).

- Energy focus: New materials like graphene, ceramics.

VIII. Conclusion

Air heaters are vital in industrial thermal systems. They have evolved from simple resistance heaters to intelligent, modular units. Green industry and smart manufacturing demand more. Air heaters will play bigger roles in energy saving, safety, and eco-friendliness. Choosing the right heater requires careful thought. Consider technical specs, environment, and safety for optimal system performance.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com