As an important part of industrial and civil thermal energy equipment, boiler is widely used in various fields. Its main function is to convert into heat energy by burning fuel for heating, steam production, hot water supply and so on. The boiler system not only includes the core boiler body, but also involves many supporting facilities and piping systems, such as combustion equipment, heat transfer system, control system and so on. Different types of boilers are suitable for different application scenarios, so the selection needs to be based on the actual demand, fuel type, boiler capacity and other factors to be considered.

The basic components of a boiler

The main components of a boiler system include the following:

- furnace: The core of a boiler where fuel is burned to release heat energy. Furnace chambers are usually designed to accommodate different types of fuels and ensure that they burn adequately.

- hot surface: The parts of the boiler used for transferring heat mainly include water-cooled walls, superheaters, economisers etc. These heating surfaces transfer the heat generated by combustion to the work mass (water or steam) by means of different heat transfer methods (radiation, convection, etc.).

- Combustion systems: The burner is a very important piece of equipment in a boiler and is responsible for mixing the fuel with air to provide sufficient fire. Depending on the type of fuel, the design of the combustion system will be different.

- Soda system: The work medium in a boiler is usually water, which is heated to steam, which is then piped to the user. The steam system includes water supply, steam piping, and drain piping.

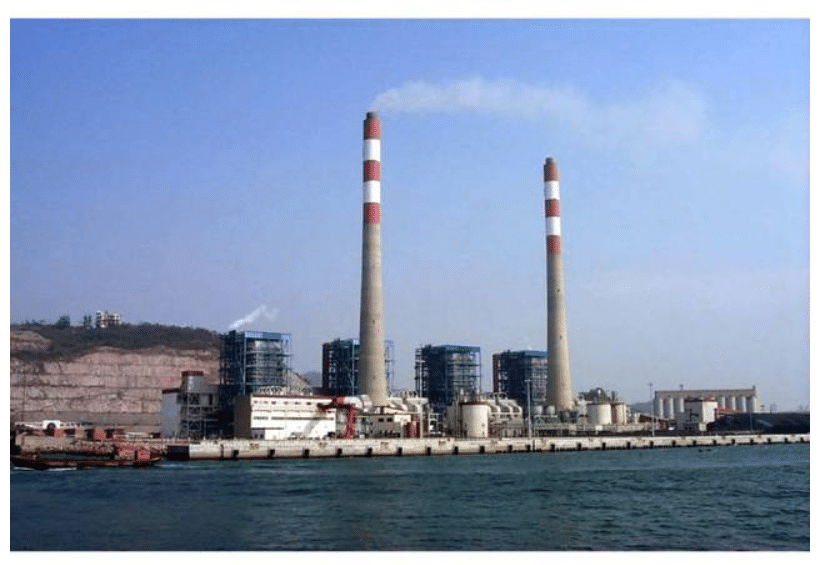

- Flue gas emission system: The flue gas produced by the boiler needs to be discharged out through the flue, and it also needs to be equipped with flue gas treatment equipment, such as desulphurisation and denitrification devices, in order to reduce the pollution to the environment.

- control system: Modern boilers commonly use automated control systems, which can monitor the parameters of boiler operation in real time, such as temperature, pressure, flow, etc., to ensure that the boiler operates in a safe and efficient state.

Types of Boilers and Applications

According to the type of fuel used, working pressure, temperature and other characteristics, boilers can be divided into a variety of types, the following are common types:

- gas boiler: Combustion is mainly carried out through clean energy sources such as natural gas and liquefied petroleum gas. Due to high combustion efficiency and low pollution, gas boilers are widely used in industrial and domestic heating and hot water supply.

- gas boiler: Suitable for boilers fuelled by gas, mostly used in areas where there is an abundant supply of fuel.

- steam boiler: It is mainly used in industry, power plants, heating systems, etc. by heating water and converting it into steam.

- hot water boiler: A boiler used to produce hot water, commonly found in heating, ventilation and air conditioning (HVAC) systems and large-scale heating systems.

- oil boiler: Oil-fuelled boilers, although more costly to use, are still in demand in some oil and gas-rich regions.

Boiler efficiency and energy saving technology

Boiler efficiency is a key indicator for measuring the economy of boiler operation, which indicates the ratio of the heat that can be effectively utilised by the boiler to the total heat released by fuel combustion. The key to improving boiler efficiency lies in optimising the combustion process, improving heat exchange efficiency and reducing heat loss. Modern boiler systems also use a variety of energy-saving technologies, for example:

- economiser: By recovering the waste heat of flue gas to heat the feed water, the boiler feed water temperature is increased and the fuel consumption is reduced, thus improving the boiler efficiency.

- air preheater: By utilising the waste heat of the boiler flue gas to heat the air entering the furnace chamber, the air temperature is raised, effectively improving the combustion conditions and reducing energy wastage.

- Frequency control technology: Using frequency converters to adjust the speed of fans and pumps to achieve automatic adjustment according to load changes, thus reducing energy consumption.

- condensing technology: Condensing boilers use condensate recovery technology to recover heat from the exhaust gases and heat the return water to improve system efficiency.

Boiler Selection and Installation Considerations

Boiler selection requires comprehensive consideration of a number of factors to ensure that the equipment purchased can meet production requirements, and has a high degree of economy and reliability. The main considerations include:

- Fuel type: Different boilers are adapted to different fuels, and the right type of boiler needs to be selected according to the fuel supply situation.

- Working Pressure and Temperature: The working pressure and temperature of the boiler determine its range of use and heat output capacity, and the selection should take into account the process requirements.

- installation environment: The location of the boiler installation, space requirements and ventilation conditions will all affect the selection and layout of the boiler system.

- Energy efficiency and environmental requirements: For most businesses, improving boiler energy efficiency and reducing pollution emissions is a priority.

- degree of automation: Modern boilers commonly use automated control systems with real-time monitoring, alarms, remote operation and other functions, which help to improve the safety and efficiency of boiler operation.

Boiler equipment and its system play a vital role in industrial production, building heating, steam supply and other fields. With the development of technology, modern boilers not only have higher efficiency and lower pollution, but also can achieve intelligent and automated management. Choosing the right boiler equipment and system not only improves energy utilisation, but also reduces operating costs.

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading: