In industrial production, different types of heaters provide diverse heating options, and flange heaters have become one of the commonly used heating equipment in many industries due to their unique structure and performance advantages. This article will discuss in detail the differences between flange heaters and other heaters in terms of structure, application, energy efficiency, etc., to help users better choose the right heating equipment.

Structural features of flange heaters

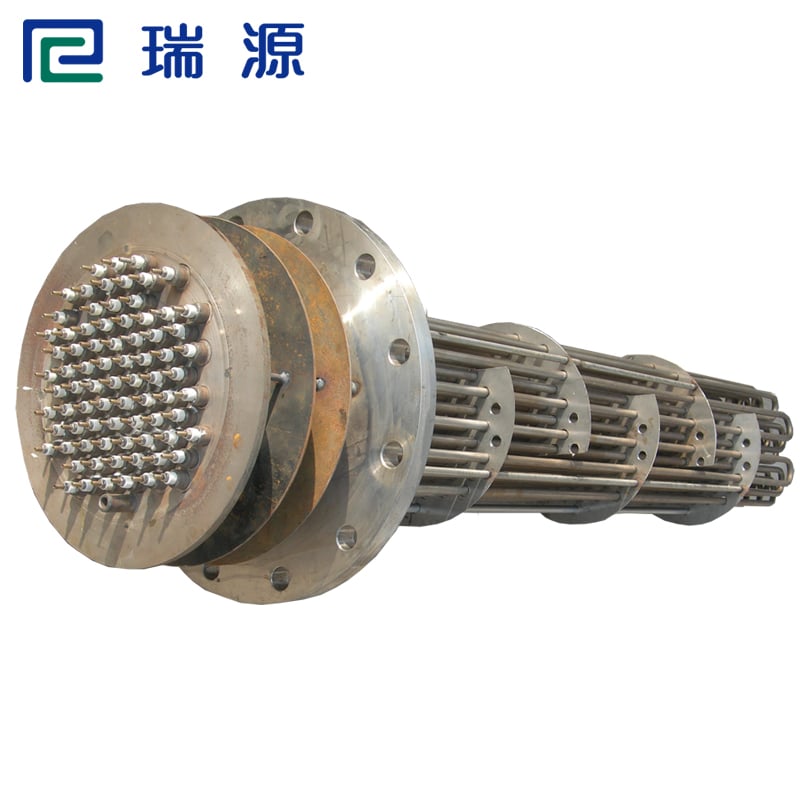

The core structure of the flange heater consists of an electric heating element and a flange mounting interface. The design of the flange mounting interface makes it easy to install the device directly into pipelines, tanks and other heating vessels, which greatly improves the installation efficiency and robustness of the device. Compared with other heaters that require additional brackets or specific installation environments, flange heaters can be more flexible to adapt to the heating needs of different industrial environments.

Flexibility in the application of flange heaters

Flange heaters are widely used in the chemical, food, pharmaceutical, energy and other fields, and their application flexibility comes from their wide range of suitable media, including air, water, oil, steam and various industrial gases. In contrast, other heaters may only be suitable for specific media, such as air heaters for air heating, while thermal oil heaters are designed for oil heating. The advantages of flange heaters in the choice of heating medium make them more widely used and adaptable.

Energy efficiency and temperature control accuracy

Flange heaters offer significant advantages in terms of energy efficiency and temperature control accuracy. It is often equipped with a temperature control system that can accurately regulate and maintain the set heating temperature. This advantage is especially important in industrial processes that require precise temperature control. Other types of heaters may not be as accurate in temperature control as flange heaters, especially in delicate production processes that require higher temperatures, where flange heaters excel. In addition, because flange heaters are installed directly in the vessel or pipeline, the energy transfer efficiency is higher, thus reducing heat loss and making heating more energy-efficient.

Ease of installation and maintenance

The flange interface design of flange heaters makes it easier to install and remove the equipment, making them suitable for industrial environments where equipment is frequently replaced. Other heaters, such as immersion heaters and air heaters, can be more complicated to install and even require specific brackets or support devices. Flange heaters are easier to maintain and replace, reducing downtime for equipment maintenance and increasing productivity.

safety

Flange heaters are often designed with multiple safety features, such as overheat protection and short circuit protection, to ensure greater safety when working for long periods of time. In contrast, other types of heaters may not be designed with as many protections as flange heaters, so flange heaters perform better in ensuring safe production.

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading:

Working Principle of Air Heater - Jiangsu Ruiyuan Heating Equipment Technology Co.