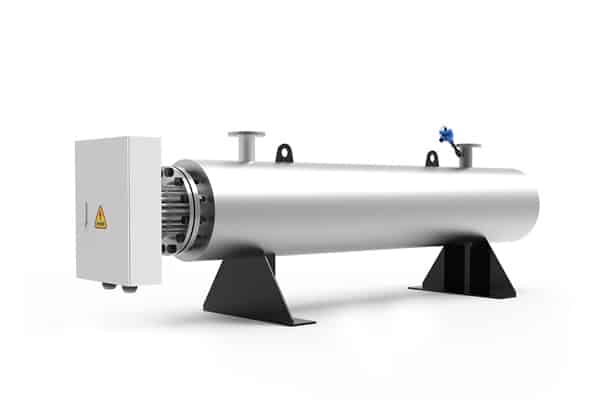

In industrial production environments, precise temperature control and stable hot air supply are critical for product quality, process stability, and energy management. Industrial-grade electric air heaters,https://8ruiyan.com/en/all-air-heaters/ with their rapid response, precise temperature control, and clean energy characteristics, have become core equipment in fields such as food drying, spray booths, and electronics cleanrooms. This guide provides an in-depth analysis of the technical specifications, installation standards, and smart maintenance solutions for industrial electric heaters.

I. Core Technical Specifications of Industrial Electric Heaters

Core Components

- Heating Elements:

- Stainless steel finned tubes (≤300°C)

- Ceramic-encased resistance wires (≤650°C)

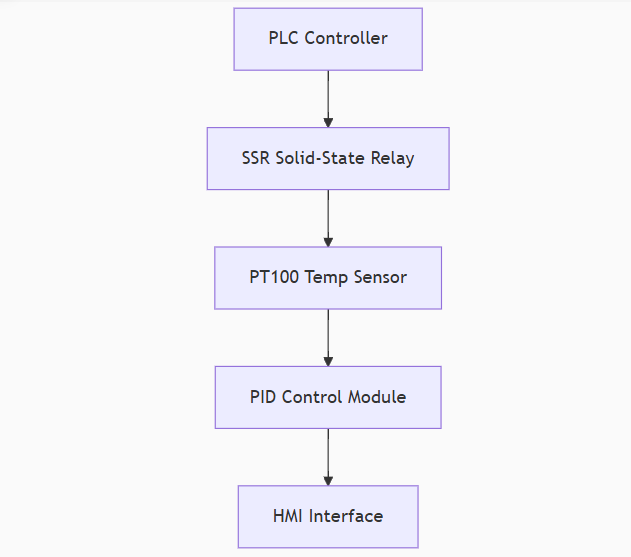

- Control System:

II. Professional Selection Guide

1. Heat Load Calculation Formula

text

Q = 0.336 × L × Δt × ρ × Cp Where: Q = Required heating power (kW) L = Airflow rate (m³/h) Δt = Temperature rise required (°C) ρ = Air density (kg/m³) Cp = Specific heat capacity (kJ/kg·K)

2. Typical Industry Applications

- Food Drying:

- Temp range: 40-120°C

- Recommended model: Duct-mounted stainless steel heaters

- Special requirement: IP65 protection

- Spray Booths:

- Temp range: 25-80°C

- Essential feature: Explosion-proof design

- Airflow requirement: 15-20 air changes/hour

III. Engineering Installation Standards

1. Electrical Installation

- Power Supply Requirements:

- 380V 3-phase 5-wire system

- 125A breaker per 100kW

- Cable cross-section calculation:textS = I × L / (K × ΔU) Where: I = Operating current (A) L = Cable length (m) K = Conductivity coefficient (57 for copper) ΔU = Allowable voltage drop (≤5%)

- Safety Systems:

- Multi-stage protection circuits

- Ground resistance ≤4Ω

- Leakage protection trip current ≤30mA

2. Mechanical Installation

- Ductwork Connection Standards:

- Straight duct before/after heater ≥3× pipe diameter

- High-temp gaskets for flange connections

- Expansion joint allowance ≥5mm/m

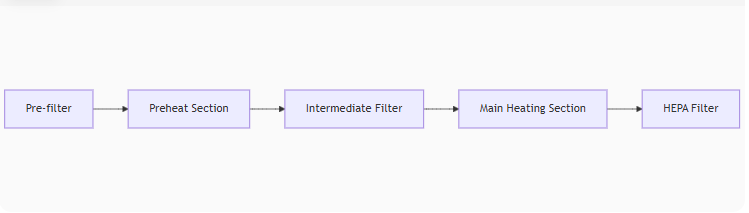

- Typical Installation Layout:

IV. Commissioning Procedures

1. First Startup Checklist

- Insulation test (≥2MΩ)

- Phase sequence check (3-phase systems)

- Fan rotation verification

- Safety interlock test

- Sensor calibration

2. Step-by-Step Startup

python

# Automated control logic example

def system_start():

start_blower() # Start fan first

delay(30) # 30s pre-purge

enable_heater(25%) # 25% power warm-up

ramp_up(5%/min) # 5% power increase/min

while True:

adjust_power() # PID control

check_alarms() # Safety monitoring

3. Operational Monitoring

- Key Parameters:

- 3-phase current imbalance <10%

- Outlet temp fluctuation <±2°C of setpoint

- Heating element surface temp < max allowed

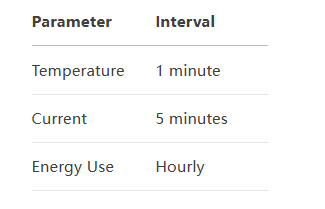

- Data Logging Frequency:

Conclusion

The selection and maintenance of industrial electric air heaters involve multidisciplinary systems engineering spanning thermodynamics, electrical automation, and mechanical design. We recommend:

- Implementing structured inspection routines

- Deploying condition monitoring systems

- Conducting regular thermal efficiency tests

- Maintaining comprehensive operation logs

With smart upgrades and precision management, system efficiency can improve by 15-25%, while annual maintenance costs may decrease by over 30%. Contact our engineering team for customized solutions.

For technical inquiries, contact Ruiyuan’s official support team!

📞 📞 📞

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com