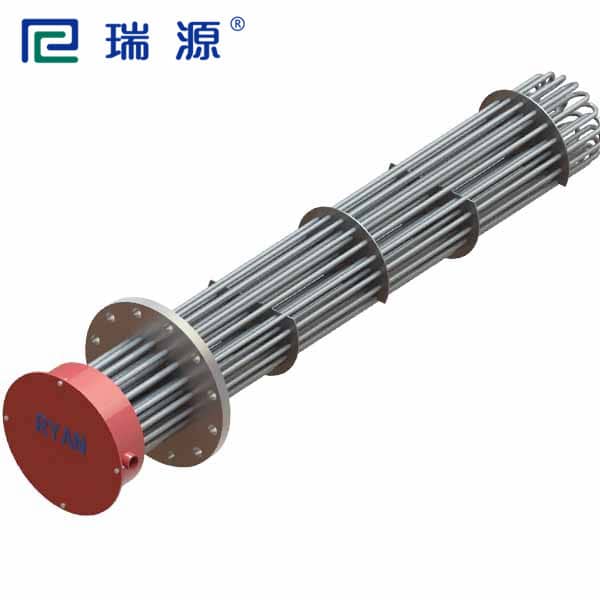

In modern industrial production, electric thermal oil heaters https://8ruiyan.com/en/all-organic-heat-carrier-boilers/have become essential equipment for many industries. The heating elements, as their core component, have a lifespan that directly impacts production efficiency and operating costs. The heating element is the key part that converts electrical energy into thermal energy. It works by placing an electric heating component inside a metal tube, with the gaps tightly filled with crystalline magnesium oxide powder, which has excellent heat resistance, thermal conductivity, and insulation.

The lifespan of a heating element is significantly affected by usage conditions and cannot be generalized. However, by following correct methods and precautions, we can effectively extend the service life of the heating elements in thermal oil heaters, reducing equipment maintenance costs.

1. Factors Affecting Heating Elements Lifespan

The lifespan of an electric heating element is not fixed. It is influenced by several factors. Among them, power design and material selection are two of the most critical.

In heating element design, surface load is an important parameter. A higher surface load leads to a shorter heating element lifespan. This is why many manufacturers use multiple heating elements. This allows for more uniform heat distribution in the thermal oil heater, reducing carbon buildup.

Regarding materials, the heating elements in thermal oil heaters should be made of stainless steel 304. Some manufacturers use iron heating elements to reduce costs. Iron is prone to rust, leading to a shorter service life.

Besides these inherent factors, usage and maintenance practices also greatly affect the heating element’s lifespan. This includes the quality of the thermal oil, operating habits, and routine maintenance.

2. Methods to Extend Heating Elements Lifespan

Methods to Extend the Service Life of Heating Tubes

Regularly Remove Carbon Deposits

When there is heavy carbon buildup, the heating tube should be removed. Clean off surface oil and carbon deposits. Carbon buildup increases surface temperature and raises the surface load, shortening the tube’s lifespan. Regular cleaning helps maintain good working condition.

Always allow the equipment to cool completely before cleaning. This prevents burns and avoids damaging the heating tube. Use suitable cleaning agents and tools to gently remove carbon and oil residues. Avoid sharp tools that could scratch the surface.

Use High-Quality Heat Transfer Fluid

Use high-quality heat transfer fluid. Replace the fluid promptly if it is of poor quality. Impurities in the fluid can form carbon deposits on the heating tube, affecting its service life.

High-quality heat transfer fluid offers better thermal stability and oxidation resistance. It reduces coking and carbon buildup on the heating tube surface. Regularly check the fluid quality and replace it according to the manufacturer’s recommended intervals. This is key to extending the heating tube’s life.

Follow Proper Shutdown Procedures

When shutting down the thermal oil unit, allow the temperature to drop below 80°C first. This helps prevent pump damage and reduces carbon buildup.

A sudden shutdown at high temperature traps heat around the heating tube. This causes residual oil to decompose and form coke. A proper shutdown allows gradual cooling. It avoids thermal shock and carbon formation.

Ensure Good Heating Tube Design

The length and design of the heating tube should consider surface load. This requires calculation and testing. Choosing a well-designed heating tube is essential for long service life.

When selecting a heating tube, ensure its surface load meets application requirements. Prefer multi-group designs for more even heat distribution. Purchase from reputable manufacturers to guarantee design and manufacturing quality.

3. Structure and Working Principle of Heating Elements

Understanding the structure and working principle helps in better use and maintenance.

The electric heating component consists of a metal tube, a spiral resistance wire, and crystalline magnesium oxide powder. The powder offers good thermal conductivity and insulation. High-temperature resistance wires are evenly distributed inside a seamless stainless steel tube. The gaps are densely filled with the magnesium oxide powder.

This structure is advanced. It offers high thermal efficiency and even heat distribution. When current passes through the resistance wire, heat is generated. This heat transfers through the magnesium oxide powder to the metal tube surface. It is then transferred to the object being heated or the air.

4. Precautions During Operation

Besides the methods above, paying attention to the following points during daily operation can also help extend the heating element’s life:

Avoid dry firing of the heating element. If the oil level falls below the element, dry firing occurs. The tank contains high-temperature oil vapor and combustible gases. This can lead to tank explosion, which is very unsafe.

Regularly check the terminals and connecting wires of the heating element. Ensure electrical connections are secure. Poor contact can cause local overheating.

Follow the operation manual provided by the equipment manufacturer. Do not overload the equipment. Ensure the heating element operates under rated conditions.

Heating Element Daily Maintenance Checklist

| Check Item | Normal Standard | Check Frequency |

|---|---|---|

| Surface Carbon Buildup | No obvious carbon | Weekly |

| Terminal Tightness | No looseness | Monthly |

| Insulation Resistance | >1MΩ | Every six months |

| Connection to Pipes | No leakage | Weekly |

| Thermal Oil Quality | Clear, no impurities | Every three months |

5.Conclusion

Choosing quality heating elements, using high-grade thermal oil, operating correctly, and maintaining regularly—these seemingly simple methods are the true secrets to extending the life of heating elements in electric thermal oil heaters.

There are no shortcuts in equipment maintenance. Only by perfecting the details can smooth operation of the production line be ensured. This is how to gain an advantage in intense market competition.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com