Uneven heating in electric thermal oil heaters https://8ruiyan.com/en/all-organic-heat-carrier-boilers/ can reduce thermal efficiency, lead to equipment failure, cause poor heating performance, and even create safety hazards. Therefore, manufacturers need to take effective measures to ensure uniform heating. Below are some common solutions:

Optimize the Layout and Design of Heating Elements

Even Distribution of Heating Elements:

The layout of heating tubes (or electric heating rods) is critical for uniform heating. Manufacturers should arrange heating elements reasonably based on the furnace size and heating requirements. Avoid clustering or spreading heating elements too widely to ensure even heat distribution across all areas.

Multi-Zone Heating Design:

Divide the heating elements into multiple zones and control the temperature of each zone separately. This design helps manage temperature differences and prevents localized overheating or underheating.

Accurate Temperature and Power Control

Smart Temperature Control System:

Advanced temperature control systems, combined with sensor technology, can monitor real-time temperature changes and automatically adjust heating power. The system can dynamically regulate the power of heating elements based on the temperature needs of different zones, achieving uniform heating.

PID Control:

Use PID (Proportional-Integral-Derivative) control algorithms to precisely manage heating power. This minimizes temperature fluctuations, improves heating stability, and reduces uneven heating caused by temperature variations.

Improve the Selection of Heating Elements

Use High-Quality Heating Elements:

Choose efficient and fast-responding heating elements, such as nickel-chromium alloy heating tubes or ceramic heaters. These elements heat more evenly and respond quickly, preventing localized overheating or underheating.

Prevent Aging of Heating Elements:

Aged heating elements may cause uneven heating. Regularly inspect the condition of heating elements and replace or maintain damaged ones in time to ensure consistent heating performance.

Optimize Internal Circulation and Fluid Flow

Enhance the Thermal Oil Circulation System:

Poor flow of thermal oil can also lead to uneven heating. To ensure even heat distribution, manufacturers can optimize the circulation system by using suitable circulation pumps, pipeline designs, and flow control devices. This ensures uniform flow of thermal oil in the heating tubes and avoids oil temperature extremes.

Improve the Flow Path of Thermal Oil:

Design the flow path and velocity of thermal oil reasonably to avoid uneven flow or stagnant areas. Uniform oil flow effectively transfers heat from the heating elements to the entire system, reducing localized overheating or temperature imbalances.

Enhance the Furnace Insulation Design

Improve Furnace Insulation:

Good insulation reduces heat loss and prevents external temperature fluctuations from affecting heating performance. Using insulation materials like ceramic fiber or aluminum silicate boards improves the furnace’s insulation, ensuring stable internal temperatures and reducing localized cooling.

Prevent Heat Loss:

If the furnace insulation is poor, heat will escape to the outside, causing uneven internal temperatures. During design and manufacturing, ensure uniform and complete insulation materials for all parts of the furnace. Regularly inspect the furnace to prevent heat leakage.

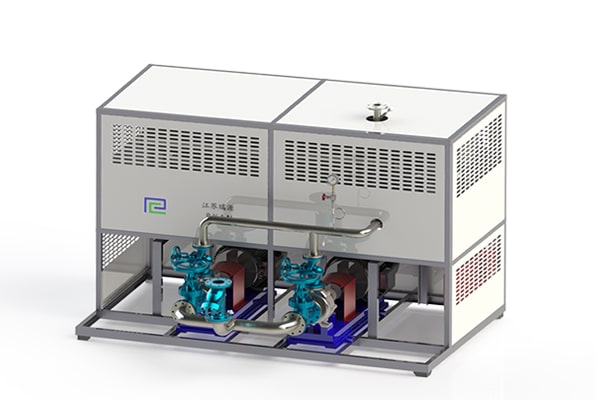

Customized Electric Thermal Oil Heaters

Add Temperature Sensors and Monitoring Systems

Install Multiple Temperature Sensors:

Place multiple temperature sensors inside the furnace to monitor temperature changes in different areas in real time. These sensors feed data back to the control system, which adjusts the power of heating elements based on actual temperatures to ensure even heating.

Heat Distribution Monitoring:

Use infrared or thermal imaging technology to monitor the heat distribution inside the furnace. This helps identify areas with uneven temperatures and optimizes the heating process. Detecting temperature differences around heating elements allows for adjustments to their operating status.

Optimize the Heating Rate

Avoid Overly Rapid Heating:

Heating too quickly may cause uneven temperatures, especially if the gas or thermal oil flow is inadequate. Control the heating rate to gradually increase the internal temperature, reducing the risk of localized overheating.

Optimize the Temperature Rise Curve:

Use a reasonable temperature rise curve to avoid sharp temperature changes, ensuring more even heat distribution.

Regular Maintenance and Care

Regularly Clean Heating Elements and the Furnace:

Carbon buildup, oil stains, or other dirt on heating elements or the furnace surface can affect heat transfer and heating performance. Regularly clean heating elements and the furnace to ensure proper operation and prevent uneven heating caused by dirt buildup.

Inspect and Replace Worn Parts:

Heating elements, sensors, circulation pumps, and other components may wear out over time, leading to uneven heating. Regularly inspect these parts and replace damaged or degraded components promptly.

Conclusion:

Uneven heating in electric thermal oil heaters can be addressed through various improvements and optimizations. These include optimizing the layout of heating elements, improving temperature control systems, enhancing circulation efficiency, strengthening furnace insulation, adding temperature sensors, and performing regular maintenance. These measures can effectively improve heating uniformity, enhance operational efficiency, and extend the equipment’s service life. If uneven heating is severe, contact the manufacturer for professional inspection and adjustment.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com