In many industries, precise temperature control is essential. Think chemical processing, pharmaceuticals, or food production. This control often happens inside a reactor.But how do you heat a reactor safely and evenly? The answer is an electric thermal oil heater https://8ruiyan.com/en/all-organic-heat-carrier-boilers/. This system is a reliable and efficient partner for your reactor.

Let’s break down how they work together.

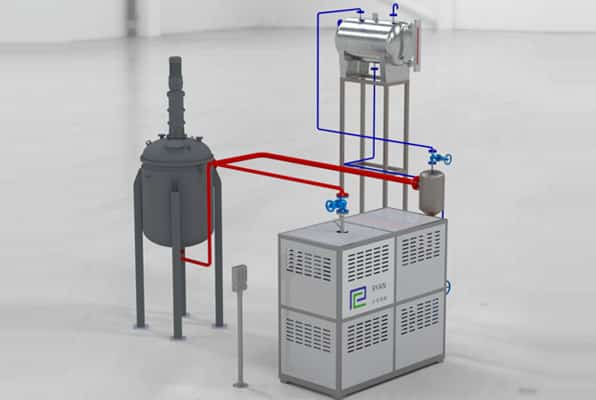

Meet the Key Players

- The Reactor: This is the main process vessel. It holds the materials for a chemical reaction. It needs exact temperatures.

- The Electric Thermal Oil Heater: This is the heating unit. It uses electricity to heat a special fluid called thermal oil (or heat transfer fluid).

- The Thermal Oil: This is the “lifeblood” of the system. It carries heat from the heater to the reactor.

The 4-Step Working Process

The process is a continuous, closed loop. It is simple and effective.

Step 1: Heating the Oil

The process starts inside the thermal oil heater. Electric heating elements warm the thermal oil. The oil absorbs the energy. Its temperature rises precisely.

Step 2: Pumping the Hot Oil

A powerful circulation pump then pushes the hot oil. It moves through insulated pipes. The destination is the reactor’s jacket.

A simple note: A jacket is a hollow shell around the reactor. It creates a space for the hot oil to flow.

Step 3: Transferring the Heat

The hot oil circulates through the reactor jacket. Heat moves from the oil, through the reactor wall, and into the materials inside. This provides gentle, uniform heating. It avoids hot spots.

Step 4: Returning and Reheating

After giving up its heat, the oil cools down. This cooler oil returns to the heater through a return line. The heater warms the oil again. The cycle repeats non-stop.

Precise Temperature Control is Key

How does the system maintain the right temperature? It uses smart controls.

- Sensors monitor the oil and reactor temperature.

- A Controller (PLC) checks the sensor data. It compares it to the setpoint.

- The controller makes adjustments. It tells the heater to work harder or to stop. It can engage a cooling system if needed.

This ensures perfect temperature stability. Your process gets the exact “recipe” it requires.

Why Use This System? Key Benefits

- High Temperature, Low Pressure: Thermal oil can reach high temperatures without high pressure. This is safer than steam.

- Uniform Heating: The jacket provides even heat distribution.

- Safety: The system is closed. The process material never contacts the heat source.

- Efficiency: The system recycles and reuses the thermal oil. This saves energy.

Conclusion

An electric thermal oil heater and a reactor are a perfect team. The heater acts as a powerful, external heart. It pumps thermal oil, the lifeblood, in a continuous loop. This delivers steady, controllable heat to the reactor.

This partnership enables safe and efficient industrial processes. It is the smart choice for precise thermal management.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com