Quality first, non-standard customisation

TEG cleaner for Chemical fibre industry

Products

Working Principle

Triethylene Glycol Cleaning Furnace

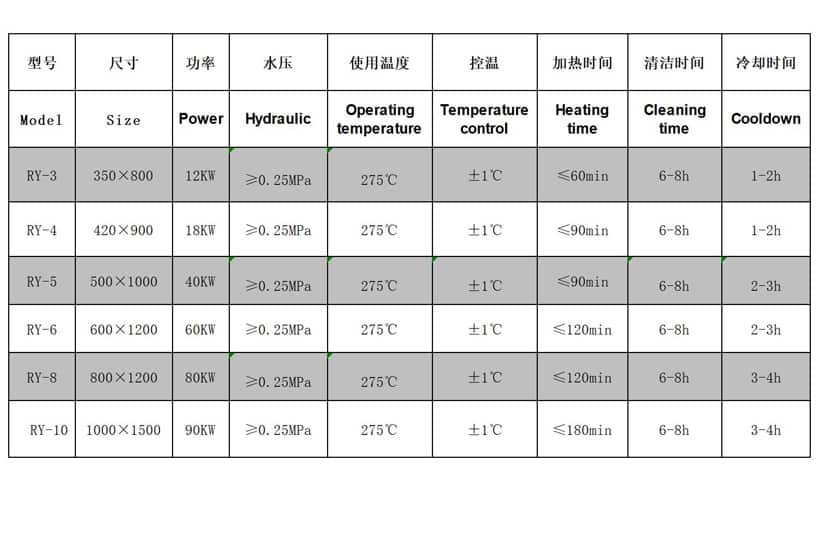

Triethylene glycol (TEG) is a colourless, transparent, neutral, oily liquid. When heated to boiling temperature, it has an alcoholic and solubilising effect on high polymer melts. Taking advantage of this property, triethylene glycol is heated to 275°C (TEG has an ultimate boiling point of 286°C), which results in the alcoholysis and dissolution of polymers adhering to the micropores of the filter cartridges or the workpieces, thus achieving the purpose of cleaning.

Product Advantage

Quality first

quality assurance (QA)

Strict quality control ensures that the quality meets the standard and enhances customer satisfaction.

quality control

rigorous standard

Equipped with the Special Inspection Institute on-site personnel, the equipment factory have been strictly inspected.

Expertise

Precision and Meticulousness

Rigorous welding, precision and meticulous, seamless welding, fine workmanship and exquisite.

Cleaning effect

Product Advantage

Precise temperature control and cleanliness

Professional After Sales

factory direct

quality assurance

craftsmanship

principal

Applicable industries

01

Injection moulding process

02

extruders

03

fibre industry

03

Paint spraying process

Live Cases

Quality first

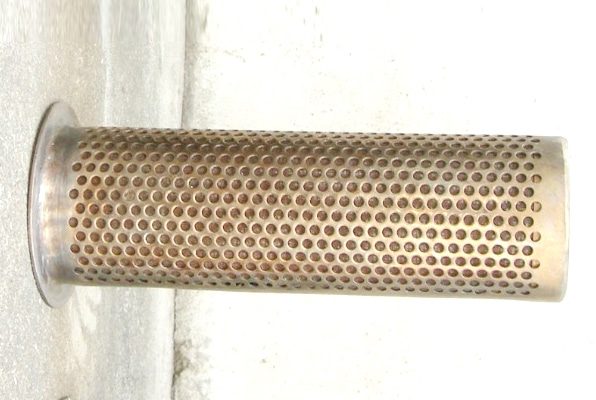

Excellent cleaning effect

Such as polymer residues on the spinneret, etc., so that the cleaned parts plate surface is clean, the silk hole is smooth, and good performance is restored.

Quality first

energy-saving and efficient

Short working time and low energy consumption can reduce the operating costs of enterprises, and at the same time, the shorter cleaning cycle also helps to improve the production efficiency.

Quality first

Reliable equipment performance

Equipped with advanced temperature control system, it can precisely adjust the heating rate and maintain constant temperature.

Quality first

High degree of automation

Easy operation reduces labour intensity, improves productivity and also reduces human error.

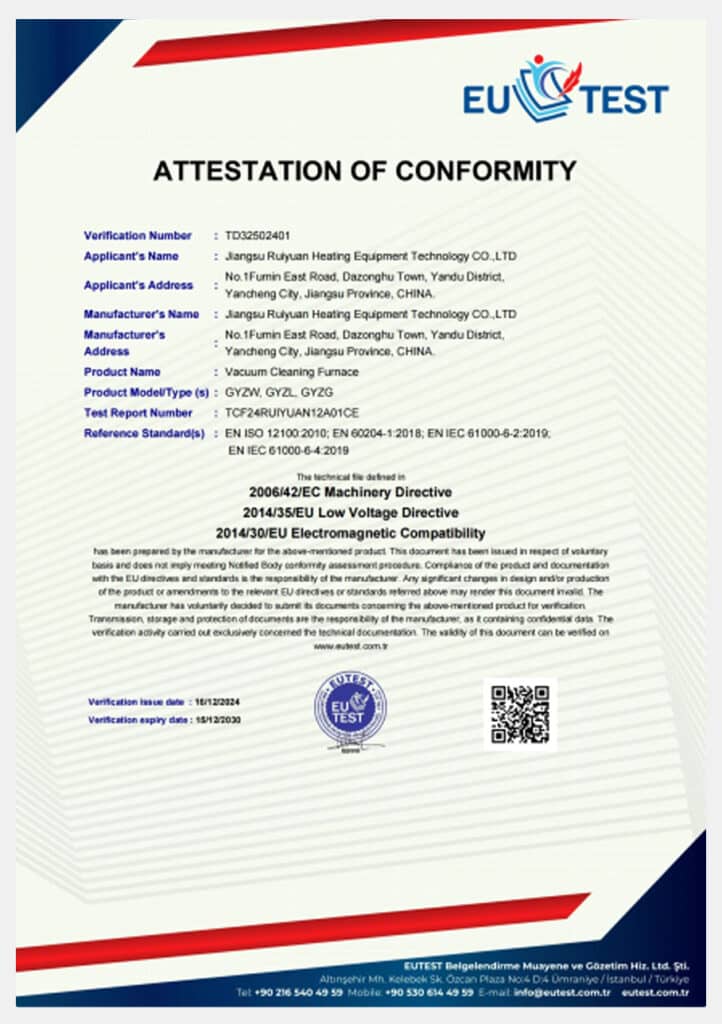

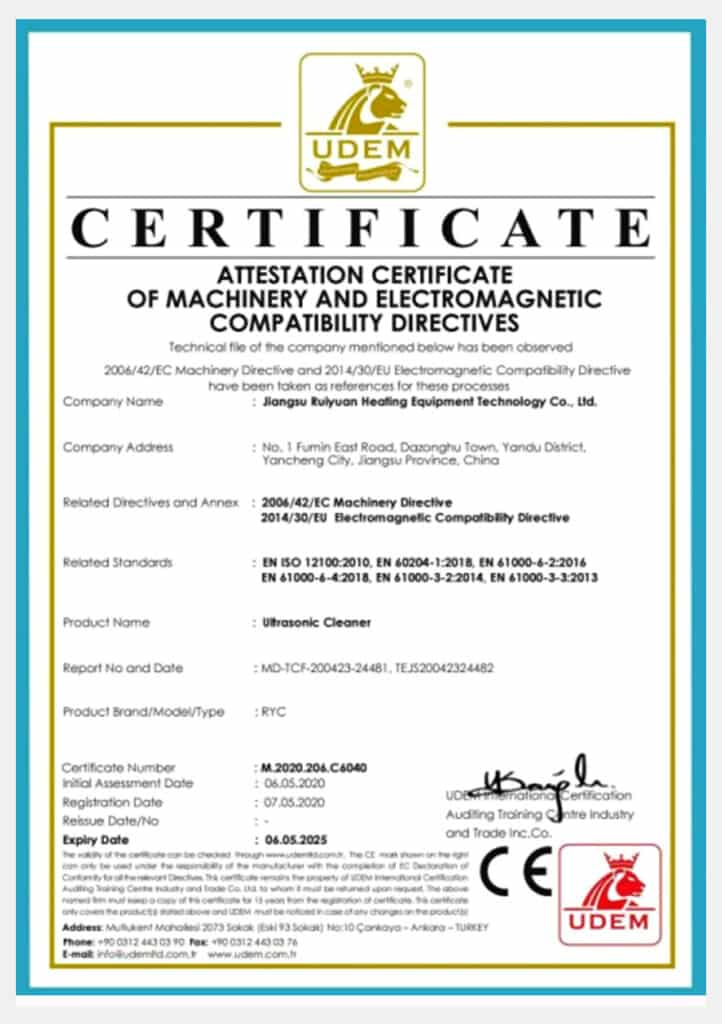

Complete qualification, reliable quality