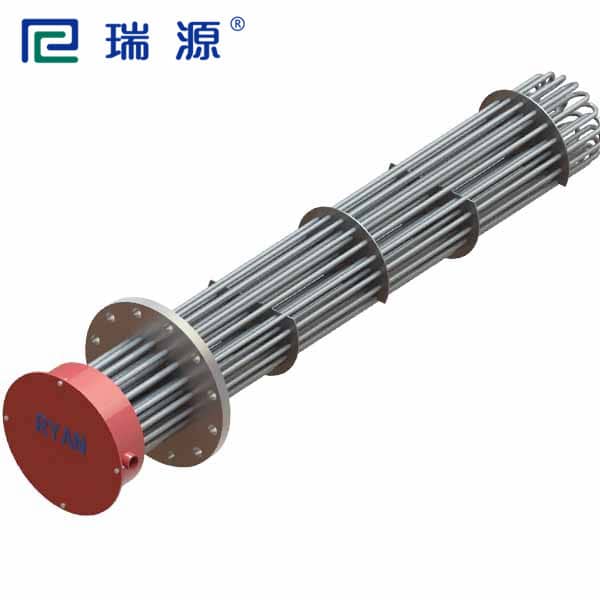

Heating tubes are the core of electric thermal oil heatershttps://8ruiyan.com/en/all-organic-heat-carrier-boilers/. They convert electricity into heat to warm the oil. Their condition directly impacts system efficiency and safety.

How Do Heating Tubes Work?

- Electricity → Heat: Current flows through internal resistance wires (e.g., nickel-chromium alloy).

- Transferencia de calor: Wires heat up, warming the surrounding insulating magnesium oxide (MgO) powder.

- Heating the Oil: Heat transfers to the metal sheath (stainless steel), then to flowing thermal oil.

Key Design: Surface load (power per unit area) is critical. Too high → oil cracking/coking; too low → wasted energy.

Why Are They Vital?

- Core Heat Source: No tubes = no heating.

- Efficiency Drivers: >95% energy conversion.

- Safety Guardians: Prevent localized overheating.

- System Lifespan: Stable operation protects oil quality.

Common Problems & Causes

- Severe Coking

- Symptoms: Thick black carbon on tubes.

- Causes: High oil temp, low flow, aged/poor-quality oil.

- Result: Poor heat transfer, energy waste, tube burnout.

- Burnout (Open Circuit)

- Symptoms: No heating; infinite resistance.

- Causes: Poor heat dissipation (e.g., coking), dry firing, high voltage.

- Result: Reduced heating power.

- Short Circuit

- Symptoms: Tripped breakers; near-zero insulation resistance.

- Causes: Damp MgO powder, voids, cracked sheath, seal failure.

- Risk: EXTREMELY hazardous! Electric shock/fire risk.

- Corrosion/Leaks

- Symptoms: Rust, pitting, oil leaks.

- Causes: Corrosive contaminants, wrong material (e.g., 304 instead of 316L stainless steel).

- Risk: Oil loss, pollution, fire hazard.

- Performance Decline

- Symptoms: Slow heating; abnormal resistance rise.

- Causes: Aged resistance wires, loose connections, degraded MgO.

- Result: Higher energy costs.

Other triggers: Voltage fluctuations, improper installation, cold-start errors.

Maintenance & Replacement Guide

1. Daily Monitoring

- Check current/voltage stability.

- Track oil temperature rise rate.

- Verify instrument accuracy.

- Test oil quality yearly (acidity, carbon residue, viscosity).

2. Routine Checks (Every 3–6 months)

- Visual Inspection:

- Examine tubes for coking, deformation, cracks, corrosion.

- Clean loose residue with a soft brush. Never scrape hard carbon!

- Electrical Tests:

- Resistance: Match initial values (±5%).

- Insulation: ≥50 MΩ (cold); ≥1 MΩ (hot). <1 MΩ? REPLACE IMMEDIATELY!

- Clean oil circuits regularly.

3. When to Replace

- Open/short circuits.

- Insulation resistance <1 MΩ.

- Deformation, bulging, cracks, leaks.

- Severe corrosion or coking.

4. Safe Replacement Steps

- DISCONNECT power! Lock out & tag switches.

- Depressurize & cool oil to <40°C.

- Drain oil from the chamber.

- Disconnect wires (label them!). Remove old tube.

- Clean the chamber and flange.

- Install new tube:

- Confirm exact specs (voltage/power/size/material).

- Test resistance/insulation before installing.

- Use new high-temp seals. Tighten bolts evenly.

- Reconnect wires correctly.

- Refill oil, purge air.

- Test-run at low temps, monitoring current/temperature.

⚠️ SAFETY FIRST!

- Only trained technicians should perform work.

- Wear PPE: heat-resistant gloves, goggles, coveralls.

- Follow protocols strictly—hot oil leaks cause severe burns/fires!

Conclusión

Heating tubes are the thermal oil heater’s “powerhouse.” Understand their role. Spot problems early. Maintain proactively. Replace correctly. This ensures safe, efficient operations. Remember: Preventative maintenance costs far less than breakdowns!

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com