1. Overview of Ducted Electric Air Heaters

A ducted electric air heaterhttps://8ruiyan.com/en/all-air-heaters/ is an electrically powered heating device installed in ventilation or air conditioning systems, primarily used to heat flowing air. It converts electrical energy into thermal energy, raising the air to the desired temperature before distributing it to the target area. Due to their easy installation, precise control, and pollution-free operation, these heaters are widely used in factories, warehouses, laboratories, and commercial buildings.

2. Working Principle

The core working principle of a ducted electric air heater is based on Joule’s Law, which states that electric current passing through a resistor generates heat. The operational process is as follows:

- Energy Conversion: When current flows through the heating element (typically resistance wire or PTC ceramic), electrical energy is converted into heat.

- Heat Exchange: A fan pushes air over the heating element, transferring heat via conduction and convection.

- Temperature Control: Built-in or external thermostats monitor air temperature and adjust heating power to maintain the setpoint.

- Air Distribution: The heated air is delivered through ductwork to the target space.

3. Key Components

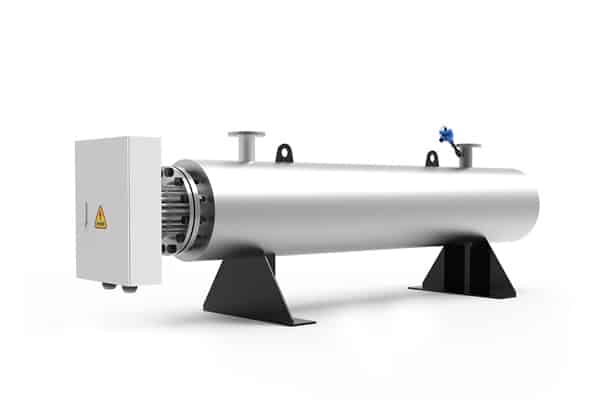

A typical ducted electric air heater consists of the following key components:

- Heating Elements:

- Resistance wire (nichrome, etc.)

- PTC (Positive Temperature Coefficient) ceramic heaters

- Electric heating tubes (metal tubes containing resistance wire and insulation)

- Housing Structure:

- Metal casing (galvanized steel or stainless steel)

- Insulation layer (minimizing heat loss)

- Flange connections (for duct attachment)

- Control System:

- Temperature sensors (e.g., PT100)

- Solid-state relays or contactors

- Control panel (programmable or basic on/off)

- Safety features (overheat protection, airflow failure switch)

- Fan System (integrated in some models):

- Centrifugal or axial fans

- Motor and speed regulation

- Auxiliary Components:

- Terminal box

- Access panel

- Mounting frame

4. Power Calculation & Selection Guide

Selecting the right ducted electric air heater requires consideration of multiple factors. Below is the basic power calculation method:

1. Basic Heating Power Formula

The required heating power can be calculated using:

text

P = Q × ρ × Cp × ΔT / η

Where:

- P = Required heating power (kW)

- Q = Airflow rate (m³/s)

- ρ = Air density (~1.2 kg/m³ at standard conditions)

- Cp = Specific heat capacity of air (~1.005 kJ/kg·K)

- ΔT = Desired temperature rise (°C)

- η = System efficiency (typically 0.8–0.95)

Simplified formula (for standard air conditions):

text

P ≈ 0.36 × Q × ΔT / η (kW)

2. Practical Selection Factors

- Ambient temperature: Minimum outdoor winter temperature

- Target temperature: Desired indoor temperature

- Airflow rate: Determined by ventilation system design

- Heat loss: Duct losses, building envelope losses

- Operating schedule: Continuous or intermittent use

- Safety margin: Typically add 10–20% extra capacity

3. Example Calculation

For heating 2000 m³/h (~0.56 m³/s) of air from -10°C to 20°C with η = 0.9:

text

P ≈ 0.36 × 0.56 × 30 / 0.9 ≈ 6.72 kW

Adding a 15% safety margin → Select a ~7.7 kW heater.

5. Advantages & Limitations

Advantages

✅ High Efficiency

- Near 100% electrical-to-thermal conversion

- Precise temperature control minimizes waste

- No combustion or flue losses

✅ Eco-Friendly

- Zero emissions (no combustion)

- Quiet operation

- Does not consume oxygen or produce fumes

✅ Easy Installation

- Compact design, minimal space requirements

- Integrates with existing ductwork

- No fuel storage or piping needed

✅ Precise Control

- Accurate temperature regulation (±1°C or better)

- Zoning and scheduling capabilities

- Compatible with building automation systems

✅ Low Maintenance

- Few moving parts (except fan) → high reliability

- Easy cleaning, minimal upkeep

- Long service life (typically 5–10 years)

Limitations

⚠ Coûts de fonctionnement

- Electricity is often more expensive than gas

- High-power units may require electrical upgrades

⚠ Power Limits

- Single units rarely exceed 100 kW (due to circuit capacity)

- Large spaces may require multiple heaters

⚠ Dependence on Electricity

- Non-functional during power outages (unless backup exists)

- Power quality affects performance and lifespan

⚠ Upfront Investment

- High-power models can be costly

- May need dedicated circuits and distribution panels

Conclusion

Ducted electric air heaters provide a clean, efficient heating solution for modern buildings and industrial facilities. By understanding their operation, correctly sizing units, and following proper installation/maintenance practices, users can maximize performance while achieving economic and environmental benefits. As technology evolves, these systems will continue advancing in efficiency, intelligence, and integration—supporting greener buildings and sustainable development.

For technical inquiries, contact Ruiyuan’s official support team!

📞 📞 📞

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com