If you are using a traditional coal-fired heater to provide thermal energy for production, you might be struggling with smoke, high energy consumption, safety risks, and labor-intensive operation. As industries upgrade, switching from coal to electric has become a smart choice for many companies. This change helps reduce costs, improve efficiency, and achieve a green transition.

Today, we will take an in-depth look at the key aspects you should focus on during this upgrade. This ensures a smooth process and stable, efficient operation afterwards.

Why Switch from Coal to Electric?

First, let’s clarify the core advantages of upgrading:

- Safety and Environmental Protection:

- Eliminates open flames, carbon monoxide poisoning, and dust pollution.

- No waste gas emissions.

- Significantly improves the working environment.

- Precise Temperature Control:

- Electric heating combined with smart temperature control systems can maintain temperature within ±1°C or even less.

- Greatly improves product quality and process stability.

- High Efficiency and Energy Saving:

- Electrical energy is directly converted into heat, with thermal efficiency reaching over 95%.

- Much more efficient than coal-fired heaters, leading to lower long-term operating costs.

- High Automation:

- Enables fully automatic operation.

- No need for dedicated staff to add coal or remove ash.

- Saves significant labor costs.

- Flexible Layout:

- No need for chimneys or large fuel storage areas.

- Equipment can be installed close to the heat usage points.

- Reduces heat loss in pipelines.

Core Considerations for the Upgrade Project

1. Preliminary Assessment and Design: Plan Before You Act

- Heat Load Calculation:

- Do not simply copy the old specs! Do not assume the new electric heater’s power should equal the old coal heater’s “heating capacity”.

- Have a professional engineer recalculate the actual heat load required by your production process. This might have changed due to optimized production lines or capacity adjustments.

- Include a Safety Margin: Add a 10%-20% safety margin to the calculated heat load for peak demand and future growth. However, avoid excessive oversizing, as it wastes energy (“big horse pulling small cart”).

- System Compatibility Check:

- Existing Pipes and Valves: Check the condition of existing thermal oil pipelines, valves, flanges, etc. Look for corrosion or blockages. Take this opportunity to clean or replace them to ensure unobstructed oil flow.

- Thermal Oil Quality: This is critical! The unstable operating temperatures of coal-fired heaters may have caused oil cracking or coking. You must completely drain and clean the system. Refill with high-quality synthetic thermal oil suitable for the electric heater’s operating temperature. Mixing old and new oil or using inferior oil is a serious risk.

- Power Capacity Application and Wiring:

- Power Determines Voltage: High-power electric heaters (usually above 100KW) require 380V industrial power. You need to apply for increased capacity from your local power supply department. Ensure transformers and lines can handle the new load.

- Professional Wiring: A certified electrician must install dedicated power cables. They must also set up an independent distribution cabinet with air switches, contactors, and overload protection devices.

2. Equipment Selection and Installation: Details Determine Success

- Choosing the Electric Heater Unit:

- Heating Type: Common types are flanged electric heating tubes and ceramic heating elements. Flanged types are easier to replace individually, simplifying maintenance.

- Explosion-Proof Requirements: If your production environment has flammable/explosive gases or dust, you must choose an explosion-proof electric thermal oil heater. Its control cabinet, junction boxes, etc., will have explosion-proof structures.

- Brand and After-Sales Service: Choose manufacturers with mature technology and a good reputation. Ensure spare part availability and prompt after-sales service.

- Configuring Core Safety Features:

- Redundant Temperature Control: Besides the main controller, you must have an independent over-temperature alarm and an extreme high-temperature protector (mechanical or electronic). This creates dual or even triple protection, cutting power immediately if over-temperature occurs.

- Level Protection: Install a magnetic level gauge with a low-level alarm to prevent dry firing of the heating elements.

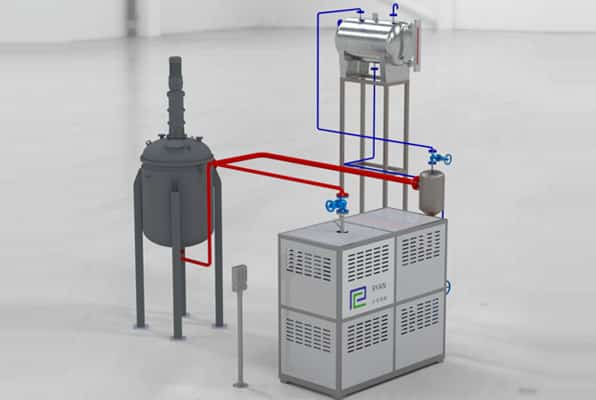

- Pressure Safety Devices: The expansion tank (high-level tank) must be installed correctly. It should have a level gauge and an overflow pipe. An automatic oil filling pump should also be set at the system’s low point.

- Installation Key Points:

- Professional Installation Team: Must be carried out by the equipment manufacturer or a qualified installation team. This ensures pipeline welding, flange connections, and electrical wiring meet standards.

- Grounding and Insulation: The equipment casing and distribution cabinet must be reliably grounded. Insulation resistance should be checked regularly.

3. Commissioning, Operation, and Maintenance: Starting a New Chapter

- System Dehydration and Deaeration:

- New oil or a cleaned system contains water and air. You must follow the steps: “low-temperature circulation -> slow heating -> constant temperature dehydration”. This gradually removes water and light components through the expansion tank. Improper execution can cause pressure fluctuations and oil spitting.

- Personnel Training:

- Operators must receive training on the new equipment. They need to understand the automated control panel. They must master startup, shutdown, parameter setting, and procedures for emergencies (like power failure, over-temperature).

- Establish a New Maintenance System:

- Regular Inspections: Check heating element resistance, contactor contacts, pump operation, and for any flange leaks.

- Regular Oil Analysis: Take oil samples every six months to a year. Test key indicators like acid value, carbon residue, and viscosity. Monitor oil aging and plan replacements proactively.

Summary: One-Time Investment, Long-Term Benefits

Upgrading from a coal-fired heater to an electric thermal oil heater https://8ruiyan.com/en/all-organic-heat-carrier-boilers/ requires upfront investment and careful planning. However, the benefits in safety, environmental protection, quality improvement, and lower long-term operating costs make it a highly worthwhile investment with a strong return.

This is a leap from “extensive” management to “refined” management. Embrace this change. Using cleaner, smarter energy empowers your business. It is not just a response to policy but a solid investment in your company’s future competitiveness.

If you are considering this plan, we recommend taking action now. Contact us for a customized, scientific, and safe upgrade solution tailored for you!

Wishing you a smooth upgrade and thriving production!

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com