If you’re working with a thermal oil heater (also called a hot oil boiler or thermal fluid heater) https://8ruiyan.com/en/all-organic-heat-carrier-boilers/ to supply heat to multiple reactors, you know that maintaining precise and independent temperature control at each reactor can be a challenge. Unlike direct heating, a thermal oil system provides indirect, uniform heating, but when several reactors share one loop, imbalances can occur. In this post, we’ll explore practical strategies to achieve better, more consistent temperature control across your reactor vessels.

The Core Challenge: One Heater, Multiple Reactors

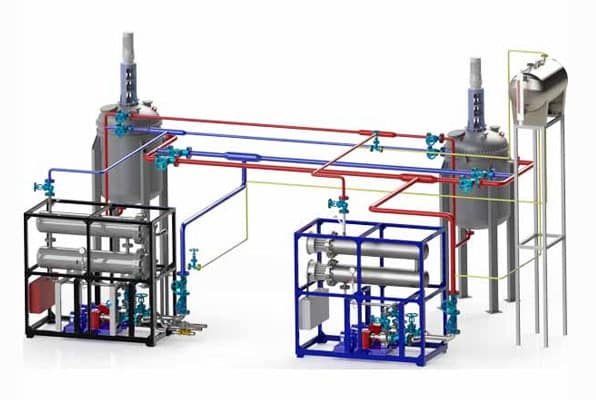

A typical setup involves one thermal oil heater circulating hot oil through a common header that branches off to several reactors. The goal is to maintain each reactor at its specific setpoint—which may differ from vessel to vessel. The main issues are:

- Heat Load Variations: Different reactors may be at different stages of a process (heating up, holding, cooling).

- Pressure and Flow Imbalances: Reactors farther from the pump may receive less flow.

- Thermal Interference: A reactor calling for cooling (by diverting flow) can affect the supply temperature to others.

Key Strategies for Improved Control

1. Optimize Your Loop Design: Parallel vs. Series

For multiple reactors, a parallel loop configuration is almost always better than series. In parallel, each reactor receives thermal oil directly from the main supply header at (roughly) the same temperature. Each branch should have:

- A dedicated control valve (preferably a modulating valve) to regulate oil flow.

- A return line back to a common return header.

This allows individual flow adjustment per reactor without drastically affecting neighbors.

2. Invest in Individual Temperature Control Valves

Each reactor branch needs its own automated control valve (globe or ball valve with actuator). This valve responds to the reactor’s temperature sensor (typically in the reactor jacket or a thermowell in the material).

- Use PID controllers: A PID controller for each reactor can adjust the valve position based on real-time temperature error, accounting for process lag.

- Three-way valves: Consider a three-way mixing or diverting valve at each reactor. It can blend hot supply oil with cooler return oil to achieve the exact jacket inlet temperature needed, minimizing shock to the reactor.

3. Prioritize Flow and Pressure Balance

Install balancing valves or flow regulators on each reactor branch during commissioning. This ensures that even when control valves modulate, the system remains hydraulically balanced, preventing one reactor from “stealing” flow from another.

4. Implement a Well-Designed Supply Temperature Management Strategy

Your thermal oil heater should have its own master temperature controller. The setpoint for the heater can be set:

- High enough to satisfy the hottest reactor demand.

- Using cascading control: The heater’s setpoint can be adjusted dynamically based on the reactor with the highest temperature demand.

5. Integrate a Efficient Return Temperature Management

High return oil temperatures can reduce heater efficiency and cause control issues. If a reactor needs cooling, consider:

- A separate cooling loop (with a heat exchanger) for that reactor’s jacket.

- A three-way valve that diverts excess heat to a cooling circuit before returning to the heater.

6. Use a Variable Speed Drive (VSD) on the Circulation Pump

A VSD allows the pump speed to adjust based on total system demand. When fewer reactors need heat, pump speed reduces, saving energy and stabilizing pressure.

7. Centralized Monitoring and Control (SCADA/DCS)

A supervisory system lets operators see all reactor temperatures, valve positions, and flow rates in real time. Alarms can flag deviations, and data logging helps optimize cycles.

Practical Example Setup

Imagine a system with one 500 kW thermal oil heater and four reactors.

- Hot oil leaves the heater at 300°C via a main supply header.

- Each reactor branch has:

- A temperature sensor (in reactor mass or jacket outlet).

- A modulating three-way valve controlled by a dedicated PID.

- A manual balancing valve (set once during commissioning).

- A jacket with good flow distribution (e.g., serpentine or half-pipe coils).

- Return lines merge into a common header back to the heater.

- The main circulation pump has a VSD controlled by header pressure.

- A PLC coordinates the heater setpoint based on the highest reactor demand.

Take aways for Better Control

- Decouple the reactors hydraulically and thermally as much as possible through parallel loops and individual control valves.

- Balance flow during commissioning—don’t overlook this step.

- Embrace automation: PID controllers and automated valves are worth the investment for repeatable results.

- Monitor return temperatures: They tell you about system efficiency and potential issues.

- Consider future expansion: Design headers and pump capacity with spare capacity for adding reactors later.

By thoughtfully designing your thermal oil distribution and control system, you can achieve precise, stable, and independent temperature control across multiple reactors—leading to better product quality, improved safety, and higher energy efficiency.

Have you tackled a similar challenge? What strategies worked in your plant? Share your thoughts in the comments below!

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com