Vacuum cleaning ovens https://8ruiyan.com/en/all-vacuum-cleaning-furnaces/have become an efficient and environmentally friendly cleaning solution in modern industrial production,,especially in the maintenance of polymer processing equipment. This article details the working principle of vacuum cleaning ovens and their standard cleaning process.

Overview of Vacuum Cleaning Ovens

A vacuum cleaning oven is a specialized device designed to remove polymer residues from industrial equipment such as molds, spinnerets, and screws. Compared to traditional chemical or mechanical cleaning methods, vacuum cleaning technology offers the following advantages:

- No chemical solvents, making it environmentally safe

- Thorough residue removal without leaving blind spots

- No damage to the base material of the equipment

- High automation level and simple operation

Cleaning process

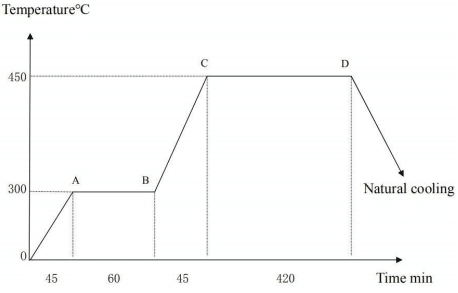

Phase 1: Heating Stage (0–300°C, 45 minutes)

The cleaning process begins with a gentle heating stage. Over 45 minutes, the furnace temperature gradually increases from room temperature to 300°C. The main objectives of this phase are:

- Softening the residual polymers gradually

- Avoiding thermal shock caused by rapid temperature rise

- Preparing for the subsequent melting stage

Phase 2: Polymer Melting (300°C, 60 minutes)

The temperature is stabilized at 300°C for 60 minutes. During this stage:

- Most thermoplastic polymers reach a molten state

- Some low-molecular-weight components begin to volatilize

- Molten polymers start to detach from the equipment surface

Phase 3: Continued Heating (300–450°C, 45 minutes)

The temperature rises from 300°C to 450°C. In this phase:

- High-melting-point polymer components begin to decompose

- Partial thermal cracking of polymers occurs

- The vacuum system effectively removes volatile components

Phase 4: Vacuum Cracking (450°C, 360 minutes)

This is the core stage of the entire cleaning process, maintaining 450°C under vacuum for six hours:

- Polymer macromolecular chains break down into smaller molecules

- The vacuum system continuously extracts cracking byproducts

- Residues are completely decomposed and removed

- The equipment surface undergoes deep cleaning

Phase 5: Oxidation Stage (450°C, 60 minutes)

While maintaining 450°C, a controlled amount of air is introduced into the furnace:

- Oxidizing residual carbides

- Further purifying the equipment surface

- Ensuring no organic residues remain

Phase 6: Cooling Stage

Finally, the system undergoes natural cooling:

- Cooling rate is typically controlled at 5–10°C per minute

- The furnace can be opened once it reaches a safe temperature

- Total cooling time depends on the equipment size

TYPICAL POLYMERS

Polyolefins: PE, HDPE, PP, PB, EVA, EVOH

Polyesters: PET, PBT, PC, PTT, PEN

Polyamides: PA6, PA6.6, PA12, PPA

Polyacrylates: PAN, PBA, PMA, PMMA

Polystyrenes: PS, ABS, SB, SBS, SAN

Biopolymers: PLA, PEA, PVAL, PPOX

Polyetherketones: PAE, PEK, PEEK

Polyimides: PI, PBI, PEI, PBO, PMI

Polyurethanes: PUR, TPA, TPO, TPU, Spandex

Special Polymers: LCP, POM, BR, NBR

Other polymers on request

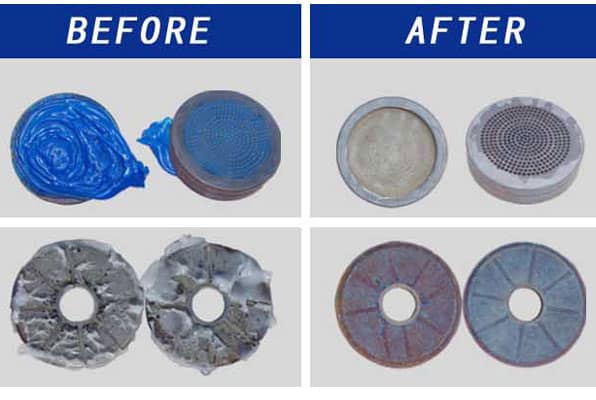

Cleaning Effect Comparison

Safety Precautions

- Ensure proper sealing before operation

- Strictly follow temperature control procedures

- Allow cooling below 80°C before opening the furnace

- Regularly inspect vacuum system performance

- Equip necessary safety protection facilities

📢 Final Recommendation:

For technical inquiries, contact Ruiyuan’s official support team!

📞 📞 📞

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com