In the field of industrial heating, gas boiler and electric thermal oil heater https://8ruiyan.com/en/all-organic-heat-carrier-boilers/are two widely used thermal energy systems. Choosing the right heating solution is crucial for production efficiency, energy costs, and environmental compliance. This article provides a detailed comparison of these technologies—covering working principles, pros & cons, and cost factors—to help you make an informed decision.

1. Working Principle Comparison

🔹 Gas Boiler System

A gas boiler generates heat by burning natural gas (NG), liquefied petroleum gas (LPG), or other combustible gases. The released heat is transferred to water via a heat exchanger, producing steam or hot water. Key components include:

✔ Bruciatore (for combustion)

✔ Heat exchanger (transfers heat to water)

✔ Water supply system

✔ Control & safety systems

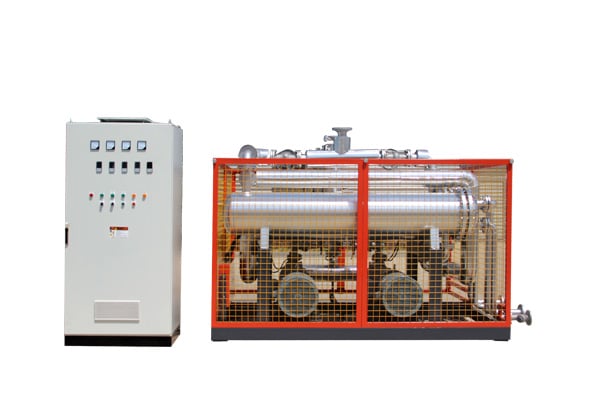

🔹 Electric Thermal Oil Heater

An electric thermal oil heater uses electrical resistance heating to warm thermal oil, which is then circulated via a pump to deliver heat. Main components:

✔ Electric heating elements

✔ Expansion tank (accommodates oil expansion)

✔ Circulation pump

✔ Filtration & control systems

2. Pros & Cons Analysis

✅ Advantages of Gas Boilers

✔ Lower operating costs (where gas is cheap)

✔ High efficiency (90%+ with condensing models)

✔ Fast heat-up time

✔ Suitable for high-power, continuous use

✔ Mature, widely supported technology

❌ Disadvantages of Gas Boilers

✖ Emissions (NOx, CO₂) → environmental concerns

✖ Explosion/gas leak risks → strict safety measures needed

✖ Requires gas infrastructure

✖ Higher maintenance (burner cleaning, heat exchanger upkeep)

✖ Larger footprint (needs a boiler room)

✅ Advantages of Electric Thermal Oil Heaters

✔ Zero on-site emissions (clean & eco-friendly)

✔ Precise temperature control (±1°C or better)

✔ Safer (no open flames, lower explosion risk)

✔ Compact & flexible installation (no flue required)

✔ Low maintenance (no burners/combustion parts)

❌ Disadvantages of Electric Thermal Oil Heaters

✖ Higher electricity costs (vs. gas in most regions)

✖ Dependent on stable power supply

✖ Limited max power (grid capacity constraints)

✖ Higher upfront cost (especially for large systems)

✖ Thermal oil degrades over time (replacement needed every 3-5 yrs)

3. Cost Breakdown

💰 Initial Investment

| System | Key Costs |

|---|---|

| Gas Boiler | Boiler unit, gas piping, flue, water treatment |

| Electric Heater | Heating elements, transformers, electrical upgrades |

💡 Electric systems typically cost more upfront, especially for high-power applications.

Operating Costs (Example: 1 Million kcal Heat Output)

| Factor | Gas Boiler | Electric Heater |

|---|---|---|

| Efficiency | 85-95% | 95-98% |

| Energy Price | ¥3/m³ (gas) | ¥0.8/kWh (electricity) |

| Hourly Cost | ~¥360 | ~¥968 |

| Annual Cost (8,000 hrs) | ~¥2.88M | ~¥7.74M |

📌 *Electric heaters are cleaner but often 2-3x more expensive to run than gas boilers.*

🔧 Maintenance Costs

✔ Gas Boiler: ~2-3% of initial cost/year (burner servicing, safety checks)

✔ Electric Heater: ~1-1.5% of initial cost/year (electrical checks, oil replacement)

⏳ Lifespan & Long-Term Costs

- Gas boilers: 15-20 years (longer lifespan)

- Electric heaters: Heating elements last 5-8 years; oil replaced every 3-5 years

4. Best Applications

When to Choose a Gas Boiler:

✔ Large-scale industrial heating (factories, refineries)

✔ Regions with cheap & stable gas supply

✔ Steam generation required

✔ Lower long-term costs prioritized

When to Choose an Electric Heater:

✔ Strict emission zones (urban areas, cleanrooms)

✔ Precision temperature control needed (pharma, food processing)

✔ No gas infrastructure available

✔ Space-constrained installations

5. Future Trends

🔮 Hybrid systems (gas + electric for efficiency)

🔮 Smart IoT integration (remote monitoring & automation)

🔮 Renewable energy pairing (solar/wind + electric heating)

🔮 Hydrogen boilers (potential game-changer for gas systems)

6. Key Decision Factors

✔ Energy costs & availability (gas vs. electricity pricing)

✔ Environmental regulations (local emission laws)

✔ Process needs (temperature precision, heat medium)

✔ Total cost of ownership (not just upfront price)

✔ Space & infrastructure constraints

📢 Final Recommendation:

For technical inquiries, contact Ruiyuan’s official support team!

📞 📞 📞

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com