We are excited to announce the successful completion and on-time delivery of a custom-engineered 80kW biphenyl generator system for a prominent textile industry client in Dongguan, China. This advanced thermal system https://8ruiyan.com/en/boiler-products/was designed and manufactured to meet the specific high-temperature process requirements of modern textile production.

Project Overview: A Tailored High-Temperature Solution

This comprehensive system provides a complete heat transfer solution specifically engineered for demanding industrial environments. The core configuration includes two high-performance heaters operating in conjunction with a shared, centralized storage tank. This setup ensures both operational efficiency and consistent thermal fluid management.

Technical Specifications & Innovative Design Features

The biphenyl generator system represents the forefront of thermal engineering with several key technological advancements:

1. Robust High-Temperature/Pressure Design

- Engineered for a maximum design temperature of 350°C and a design pressure of 0.2MPa.

- The primary vessel is constructed with 8mm thick material, providing exceptional structural integrity and long-term durability under continuous high-stress operation.

2. Centralized Fluid Management System

- Features a dedicated Φ1000×1500 mm biphenyl storage vessel serving both heating units.

- Equipped with dual-level indicators, precision thermometers, pressure gauges, and a primary safety valve for comprehensive fluid monitoring and safe storage.

3. Multi-Layered Safety Architecture

- Integrated safety valve (calibrated to open at 0.25MPa) paired with a rupture disc assembly (set at 0.26MPa) for redundant pressure relief.

- Additional safeguards include dry-fire prevention thermocouples and an electrical contact pressure gauge, creating a protective matrix against over-temperature, over-pressure, and dry-running hazards.

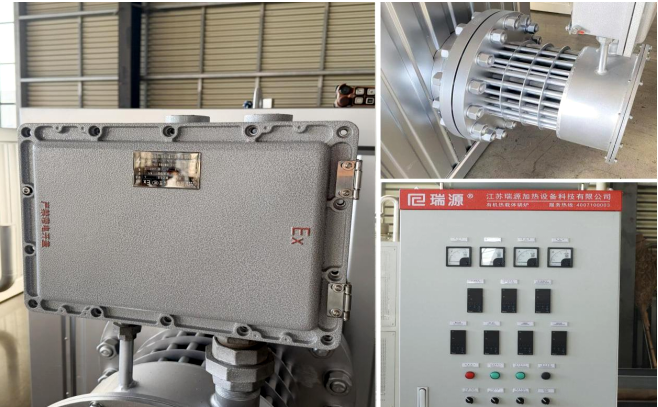

4. Explosion-Proof Operational Integrity

- All critical field instruments, including level and pressure indicators, are certified explosion-proof and rated for continuous operation at 350°C.

5. Premium Electrical & Control System

- Core electrical components feature Schneider Electric products for maximum reliability.

- The system includes a control cabinet with 50 meters of integrated cable and an explosion-proof terminal junction box for secure field connectivity.

6. Enhanced Process Monitoring Capability

- The control architecture was customized to integrate 4 additional PT100 temperature signal inputs as per client request, enabling sophisticated multi-zone temperature profiling and process control.

Commitment to Industrial Thermal Excellence

Jiangsu Ruiyuan specializes in delivering safe, stable, and high-efficiency thermal energy solutions across diverse industrial sectors. Our portfolio, ranging from electric thermal oil heaters and air heaters to specialized biphenyl systems, supports critical processes for clients nationwide. We are dedicated to providing the thermal power that drives innovation and creates tangible value for our partners’ operations.

This project underscores our capability to execute complex, custom-engineered thermal solutions that combine operational performance with uncompromising safety standards.

For further problems about clogged vacuum cleaning furnace, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com