Many industries need precise air temperature control. This includes semiconductor manufacturing, pharmaceuticals, and food processing. A stable temperature within ±1°C precision is often critical. It ensures product quality and process consistency.

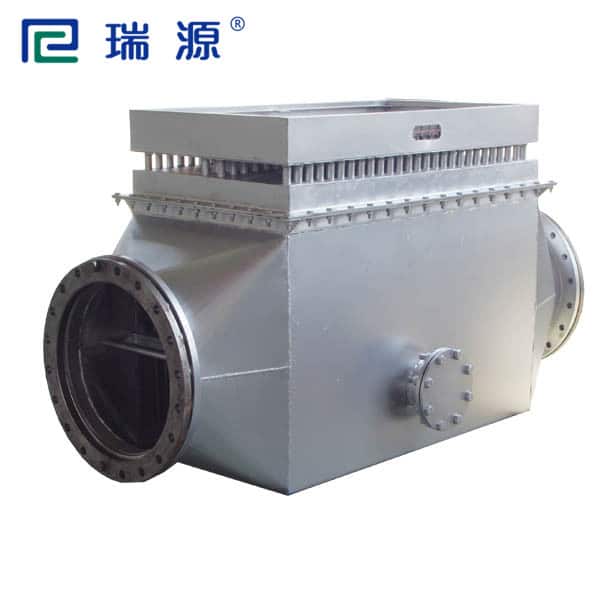

An electric air heater https://8ruiyan.com/en/all-air-heaters/ seems simple. It uses electricity to heat a element. Then a fan blows air over it. But how does it achieve such precise temperature control? The secret lies in two key areas: smart PID control algorithms and smart airflow design.

Part 1: The Challenge – Why is Precise Temperature Control So Hard?

An air heating system has high inertia and time delays (lag).

- Thermal Mass: The heating element and its housing have mass. They take time to heat up and cool down.

- Lag: It takes time for hot air to travel from the element to the sensor.

- Disturbances: Changes in incoming air temperature, airflow, or voltage can affect the output temperature.

Simple “on/off” control causes big temperature swings. The power is either fully on or completely off. This is too crude for ±1°C precision. The temperature would oscillate wildly above and below the setpoint.

Part 2: The Brain – PID Algorithm

De PID controller is the smart brain. PID stands for Proportional, Integral, and Derivative. It calculates the perfect power level needed.

Think of it like adjusting a shower’s temperature:

- P (Proportional) – “The Present”:

- It looks at the current error. This is the difference between the setpoint and actual temperature.

- A large error means it applies high power. A small error means low power.

- Problem: It can settle near the target, but often with a small, steady error (offset).

- I (Integral) – “The Past”:

- It adds up past errors over time.

- This eliminates the steady offset that P control leaves behind.

- Risk: Too much I action can make the system slow and cause overshoot.

- D (Derivative) – “The Future”:

- It predicts the future by measuring how fast the error is changing.

- If temperature is rising very fast, it reduces power early to prevent overshoot.

- Risk: It can be sensitive to sensor noise.

Working Together:

Well-tuned PID parameters combine these three actions. The system responds quickly (P), eliminates offset (I), and prevents overshoot (D). The result is smooth, precise power control. It holds the temperature steady at ±1°C precision.

Many modern controllers have Auto-tuning. They automatically find the best PID settings.

Part 3: The Body – Airflow Optimization Design

A smart brain needs a capable body. Good hardware design is essential.

- Efficient Heat Exchange:

- The heating element must have a large surface area. This transfers heat to the air quickly and evenly.

- Smart Airflow and Mixing:

- Poor chamber design creates hot and cold spots. The outlet temperature becomes uneven.

- Baffles, mixing chambers, or perforated plates are used. They mix the air thoroughly before it exits. This creates a uniform temperature across the entire airflow.

- Fast-Responding Components:

- The PID signal needs a fast actuator. Solid-State Relays (SSR) are used. They switch power on and off very fast (hundreds of times per second). This allows for smooth, continuous power adjustment, not just crude on/off.

- Accurate and Well-Placed Sensors:

- Sensor Quality: Use high-precision sensors like Pt100 platinum RTDs. Their own accuracy is often within ±0.1°C to ±0.3°C.

- Sensor Location: The probe must be in the right spot. It should sense the mixed air after the heating element and mixing area. It must be exposed to the main airflow for a fast response.

Part 4: The Perfect Combination

The “smart brain” (PID) and “strong body” (airflow design) work together.

- Good airflow reduces lag and unevenness. This helps the PID controller work faster and better.

- A uniform temperature field makes the system more stable. It is easier for the PID to control.

- Accurate measurement, fast switching, and smart logic combine for the final result: ±1°C precision.

Conclusie

Precise air temperature control is an engineering challenge. It combines control theory (software) with thermodynamics and fluid dynamics (hardware).

When choosing a heater, look beyond just power and size. Ask about the control method (true PID?). Ask about the internal design for airflow (mixers or baffles?). Check the quality of key parts like the sensor and SSR. This ensures you get the precision your process needs.

We hope this explains the technology behind precise temperature control!

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com