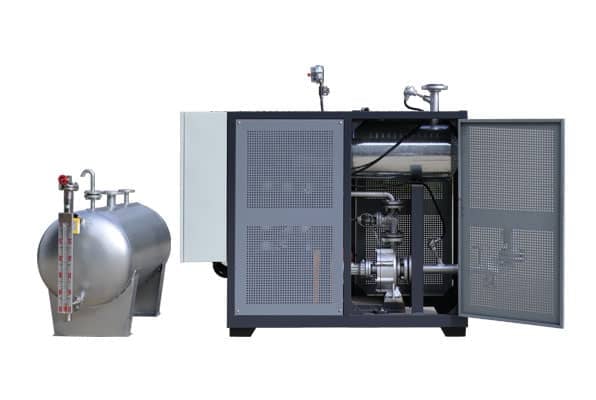

Pressure vessels https://8ruiyan.com/en/all-organic-heat-carrier-boilers/store gases or liquids under high pressure. They are everywhere. In boilers, chemical plants, and oil refineries. Their failure can be catastrophic. This is why regular safety checks are mandatory. Non-Destructive Testing (NDT) is the group of methods used for these checks. The goal is simple: find hidden flaws without causing damage.

What is NDT and Why is it Crucial?

NDT is like a medical scan for industrial equipment. It uses various technologies to “see” inside the metal. The core principle is to inspect the vessel’s integrity without cutting, drilling, or altering it in any way. It is essential for:

- Safety: Preventing leaks, ruptures, and explosions.

- Reliability: Ensuring the vessel can operate safely at its rated pressure and temperature.

- Regulatory Compliance: Meeting strict national and international standards (ASME, PED, GB).

- Cost Savings: Finding small problems early avoids expensive shutdowns and replacements later.

Common NDT Methods: The Inspector’s Toolkit

Different methods find different types of flaws. A thorough inspection often uses several together.

- Ultrasonic Testing (UT)

- How it works: High-frequency sound waves are sent into the material. The reflected waves are analyzed.

- Finds: Internal cracks, voids, corrosion thinning, and weld defects deep inside the wall.

- Best for: Measuring wall thickness and finding subsurface flaws.

- Radiographic Testing (RT) – X-ray or Gamma Ray

- How it works: Radiation passes through the vessel and exposes a film or digital detector. Denser areas (like weld metal) appear lighter.

- Finds: Internal voids, inclusions, cracks, and poor weld penetration.

- Best for: Creating a permanent 2D image of a weld’s internal quality.

- Magnetic Particle Testing (MT)

- How it works: The surface is magnetized. Iron particles are applied. Flaws disrupt the magnetic field, attracting the particles into a visible line.

- Finds: Surface and near-surface cracks in ferromagnetic materials (like carbon steel).

- Best for: Quick inspection of welds and critical areas on the outside.

- Dye Penetrant Testing (PT)

- How it works: A colored or fluorescent dye is applied to the surface. It seeps into surface-breaking cracks. Excess dye is removed, and a developer draws the dye out, making the crack visible.

- Finds: Surface cracks, porosity, and leaks in any non-porous material.

- Best for: Inspecting stainless steel, aluminum, and other non-magnetic materials.

- Visual Testing (VT)

- How it works: The most basic method. Inspectors use eyes, cameras, borescopes, or drones to look for visible issues.

- Finds: Corrosion, distortion, leaks, and surface damage.

- Best for: Routine external inspections and preparing for more advanced NDT.

How is an NDT Inspection Performed? A Typical Process

- Planning & Access: The vessel is shut down, cleaned, and prepared. Safe access is arranged.

- Method Selection: Based on the material, suspected flaws, and codes, the right NDT methods are chosen.

- Execution: Certified inspectors perform the tests according to strict procedures.

- Evaluation & Reporting: Data (waveforms, images, indications) is analyzed. A formal report details all findings, including flaw location, size, and severity.

- Action: Based on the report, the vessel may be approved, repaired, monitored, or taken out of service.

Conclusion: An Investment in Safety

NDT is not an optional expense. It is a critical investment in operational safety and asset longevity. For pressure vessels, what you can’t see can hurt you. Regular, professional NDT provides the clarity and confidence needed to operate safely. It ensures these critical containers remain reliable partners in industry, not hidden liabilities. Always rely on certified professionals to perform this vital work.

For further problems about organic thermal fluid heaters, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com