Common potential hazards and handling measures for electric thermal oil heaters:

Hazards of air and moisture ingress

During operations such as oil filling, oil replacement, and maintenance of electric thermal oil heaters https://8ruiyan.com/en/all-organic-heat-carrier-boilers/, air and moisture can easily enter the system. During heating, the air expands and moisture evaporates. The volume change caused by this is far greater than the thermal expansion of the thermal oil itself. For example, at relative zero pressure, the volume of water expands about 1,600 times when evaporated. Air heated to 270°C expands approximately 5 times. If this air and moisture are not promptly discharged, it will lead to an increase in the system’s operating pressure, seriously threatening the safety of the system. Therefore, strict control of moisture and other components in the thermal oil is essential.

During the startup heating process, the exhaust valve should be repeatedly opened to discharge air, water, and the mixed vapor of water and thermal oil from the system. Additionally, attention should be paid to controlling the heating rate of the thermal oil.

Hazards of degraded thermal oil quality

Premature deterioration of thermal oil quality due to improper operation and management in the production process is one of the common issues with electric thermal oil heaters. Some thermal oils experience severe deterioration in performance indicators after just one or two years of use. Long-term operation with degraded thermal oil leads to continuous carbon buildup on the heated surface tube walls. The inner diameter of the tubes narrows, reducing thermal oil flow. The resistance of the circulation pump gradually increases, and heat transfer efficiency continuously declines. This can result in severe accidents such as coking, blockage, overheating, deformation, and tube rupture in the furnace tubes. One reason for the degradation in thermal oil quality is local overheating, which causes thermal cracking. The second reason is oxidation of the thermal oil.

If the thermal oil exceeds its specified operating temperature, local overheating occurs. This leads to thermal decomposition and polycondensation, precipitating carbon residue. It also causes a decrease in flash point, darkening of color, increased viscosity, reduced heat transfer efficiency, and coking and aging. When thermal oil comes into contact with oxygen in the air, oxidation occurs. This generates organic acids and forms polycondensed sludge, increasing viscosity. This not only shortens the service life of the medium but also causes acidic corrosion in the system. Currently, quality standards vary among domestic thermal oil manufacturers, and the quality of thermal oils produced also differs significantly. According to the “Safety Technical Supervision Regulations for Organic Heat Carrier Boilers,” thermal oils in use should be tested at least once a year for kinematic viscosity, flash point, carbon residue, and acid value.

Hazards of automatic control system failure

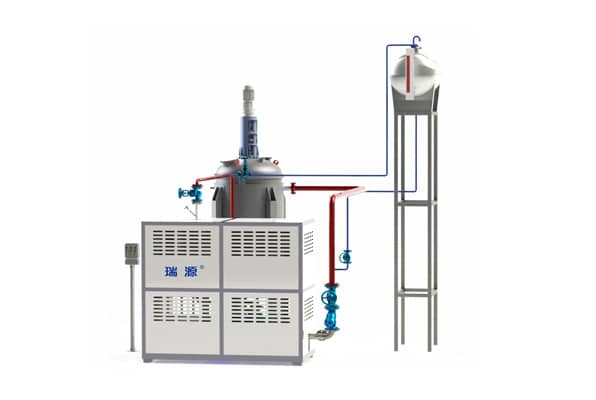

Currently, the state of thermal oil electric heater technology in China is that the control system uses a Programmable Logic Controller (PLC) as the core. Thermal oil at a certain temperature enters the heater inlet under the working pressure of the circulation pump. The thermal oil gradually heats up as it passes through the heating chamber of the heater. It then exits the outlet, reaching the required process temperature. This further enhances the automation level of the equipment.

In the control system, thermal oil is delivered by a gear pump into the entire system. When the set magnetic flap level controller reaches the specified level, the gear pump automatically stops. At this point, the circulation pump and electric heater are started to begin heating. When the outlet oil temperature reaches the set value, it enters the user’s system for circulation. The oil, after being used by the equipment, re-enters the device for heating again. This cycle repeats continuously, representing the working state of the thermal oil.

These automatic control systems are effective safeguards for the safe operation of electric thermal oil heaters. However, it is often these very safeguards that fail in actual operation due to weak safety awareness or economic reasons.

Conclusão

To ensure the safe and efficient operation of electric thermal oil heaters, it is crucial to address these common hazards proactively. This involves:

- Vigilant Management: Strictly controlling against air and moisture ingress and carefully managing the heating process during startup.

- Quality Assurance: Regularly monitoring thermal oil quality and replacing degraded oil promptly to prevent carbon buildup and system damage.

- System Integrity: Ensuring the automatic control and safety systems are fully functional, well-maintained, and never bypassed.

Ultimately, a strong commitment to safety protocols, coupled with consistent maintenance and monitoring, is essential for preventing accidents and protecting both personnel and equipment. Regular training for operators on these specific risks and the critical importance of the control systems forms the foundation of safe, long-term operation.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com