In industrial heating, quality affects efficiency, and safety determines success.

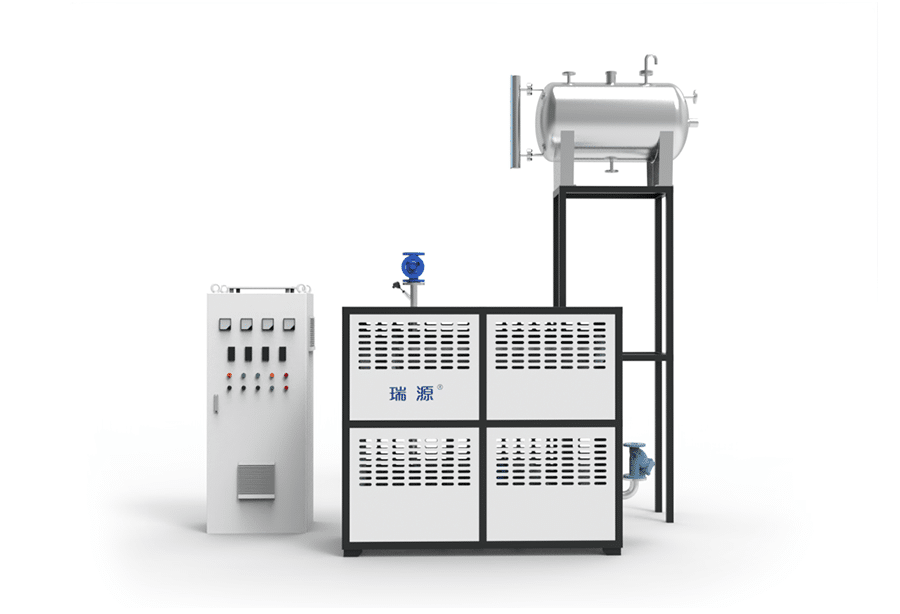

Aquecedores eléctricos a óleo térmico https://8ruiyan.com/en/all-organic-heat-carrier-boilers/are efficient and eco-friendly heating systems. They are widely used in chemical, textile, food, pharmaceutical, and many other industries. But with so many products and manufacturers, how do you choose the right one for your needs? This article answers the key questions buyers have when selecting an electric thermal oil heater.

1. Manufacturer Credentials and Reputation: Why Do They Matter?

When choosing a manufacturer, check their business licenses first. An incomplete set of credentials raises questions about product quality.

Review their qualifications as a first step. A company that has been in business for a long time is often more trustworthy. Its continued market presence suggests reliable products and stable service.

Reputation is equally important. Research the manufacturer’s standing in the industry. You can find this information online or through word-of-mouth. Good reputation usually means better product quality and after-sales service.

Get quotes from multiple suppliers. Compare them carefully. Then, choose the supplier that best fits your actual needs.

2. Equipment Configuration and Quality: How to Tell the Difference?

O components used greatly affect the price and quality. To cut costs, some manufacturers might use lower-grade parts. For example, they might use a local contactor instead of an ABB one. Such differences cause significant price variations.

Besides electrical components, also pay attention to:

- Heat resistance of the circulation pump

- Material of the heating elements

- Temperature rating of the valves

The quality of these core parts directly impacts the equipment’s lifespan and stability.

Production technology and processes are also key. Before finalizing a supplier, learn about their production equipment and workflow. Reputable manufacturers use advanced machines like CNC laser cutters and robotic welders. This ensures precision and reliable performance.

3. Temperature Control and Special Needs: How to Match Your Process?

O required temperature range directly affects the price. For example, a heater rated for 350°C will cost more than one for 180°C. Higher temperatures demand better components and pipe design.

Different industries have special requirements:

- Explosion-proof heaters cost several times more than standard models.

- Units with cooling functions are more expensive.

- O control system (e.g., PLC vs. basic controllers) also changes the price.

Good manufacturers offer customized solutions. For example, they use special materials for high-temperature processes in the chemical industry. For food processing, they can provide fully closed systems with food-grade thermal oil to prevent contamination.

4. Price: Why Such Big Differences?

Price is always a major concern. Buyers want to ensure they get good value for their money.

Besides configuration, temperature range, and special features, other factors influence price:

- Brand Value: Well-known brands often charge more but offer better quality and service.

- R&D Costs: Companies that invest in innovation reflect these costs in their prices.

- After-Sales Service: Comprehensive service support increases cost but provides peace of mind.

Price should not be the only deciding factor. The saying “you get what you pay for” often holds true for industrial equipment. Review the manufacturer’s qualifications. If possible, visit their factory.

5. Risks of Used Equipment: Is It Worth Considering?

New heaters can cost a lot. Buying a used one seems attractive. However, for critical equipment, choosing used units involves risks.

Used equipment has potential problems:

- Unknown History: It may have hidden damage or be near the end of its life.

- Worn Parts: Key components like controls, heating elements, and pumps could be old.

- Outdated Technology: Older models may be less efficient and less safe.

- No Support: It might be hard to get spare parts or professional repair service.

If you still consider a used heater, inspect it thoroughly. Check the control system, heating elements, and pump. Look for leaks, rust, or other damage. Most importantly, choose a unit from a reputable brand. Good service support is crucial for used equipment.

Conclusion: How to Make a Smart Choice?

Selecting an electric thermal oil heater requires careful thought. Follow these steps to make a better decision:

- Check Credentials: Verify the manufacturer’s licenses and history.

- Research Reputation: Look for customer reviews and industry feedback.

- Analyze Configuration: Ask about the brands and materials of key components.

- Match Your Needs: Select the right temperature range and special features for your process.

- Evaluate Price: Choose the best value within your budget, not just the lowest price.

- Review Service: Understand the after-sales service and technical support.

- Visit the Factory: See the production and quality control yourself if you can.

A high-quality electric thermal oil heaters provides stable, reliable heat. It also lowers operating costs and improves productivity. We hope this article helps you select the best heater for your needs.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com

Thanks for sharing these electrical safety tips. As a local company providing electrical installation and electrician services,

we see how proper installation and routine checks help reduce the risk of hazards

and downtime.

Thank you. Please feel free to contact us if you need any assistance. WHATSAPP +86 19106101570