What is an Explosion-Proof Pipeline Heater https://8ruiyan.com/en/all-air-heaters/? How Does It Prevent Explosions and Handle Oil, Gas, and Dust?

I. Working Principle of Explosion-Proof Pipeline Heaters

A pipeline heater is an energy-saving device used for preheating substances. Installed upstream of substance processing equipment, it directly heats the substance, enabling cyclic heating at high temperatures, ultimately achieving the goal of energy conservation.

II. Structure of the Pipeline Heater

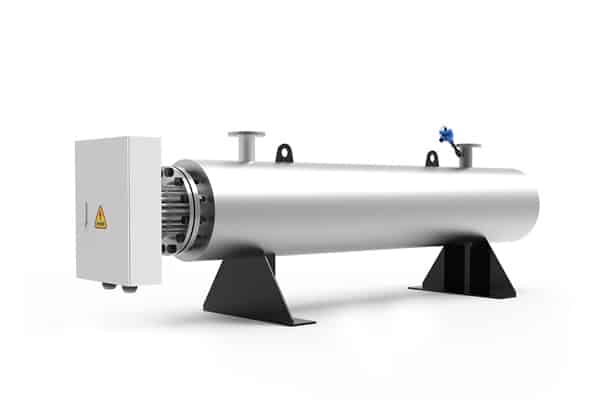

The explosion-proof electric heater consists of a terminal box, electric heating elements (heating tubes), the heater housing, and temperature control instruments and devices. The terminal box includes the junction box and the connection board for the heating tubes.

The heating element is an alloy resistance heating wire, made of Cr20Ni80. Together with the internal connection conductors, it is housed within a metal tube. The void inside the tube is densely filled with powdered magnesium oxide inorganic insulation filler. The spacing between heating elements themselves and between them and the metal tube exceeds 2 mm. The connection between the internal conductors and the heating element is achieved via crimping or hard brazing.

The terminal box is a steel structural component. It has 8 fastening bolts (specification: M12×50). The mating surface has a roughness of 3.2 μm. Cable entry devices utilize a sealed design, with sealing rings made of silicone rubber and nitrile rubber.

III. Instructions for Using the Pipeline Heater:

- Must be used in conjunction with a CNG control cabinet to achieve interlocked control.

- The operating voltage must not exceed 1.0 times the rated voltage. Both the internal and external shells must be effectively grounded.

- Operating environment: 0°C ~ 40°C (Note: Original said 340C, assumed typo for 40°C based on context), free of corrosive gases.

- Periodically inspect the surface of the heating tubes. If carbon deposits or fouling are present, they must be completely removed before use. Additionally, inspect the cylinder body and the level of corrosion annually to determine if the container or heating tubes need replacement.

- Thoroughly inspect the heater itself, along with its associated electrical equipment, instrumentation, control systems, and wiring to confirm they are intact and ready for use.

- Regularly observe whether the equipment, electrical systems, instrumentation, and control systems are functioning normally.

- Continuously monitor whether the three-phase currents are balanced.

- This equipment can be installed indoors. If outdoor installation is necessary, provide protection against rain and snow.

- Strictly control the heater’s operating temperature below 100°C to avoid combustion or explosion risks if the heating temperature exceeds the auto-ignition point of natural gas.

- According to the JB88-85 standard, the minimum service life of industrial electric heating tubes is specified as 8,760 hours. Maintain an adequate stock of spare heating tubes.

IV. How Explosion-Proof Pipeline Heaters Solve Oil, Gas, and Dust Problems

Key explosion-proof feature:

- Flameproof enclosure in the junction box. Prevents spark ignition.

Explosion protection levels vary by application.

Automatic suppression system:

- Uses ultra-fine dry powder.

- Combines chemical and physical fire suppression.

- Fully mechanical design. No electrical parts.

- Low installation/maintenance costs.

- Long service intervals. No daily upkeep.

- Fast activation.

- Evenly fills protected space. No blind spots.

- Stable explosion containment.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com

I am really delighted to glance at this web site posts which

consists of lots of helpful data, thanks for providing such statistics.

Thank you. Please feel free to contact us if you need any assistance.