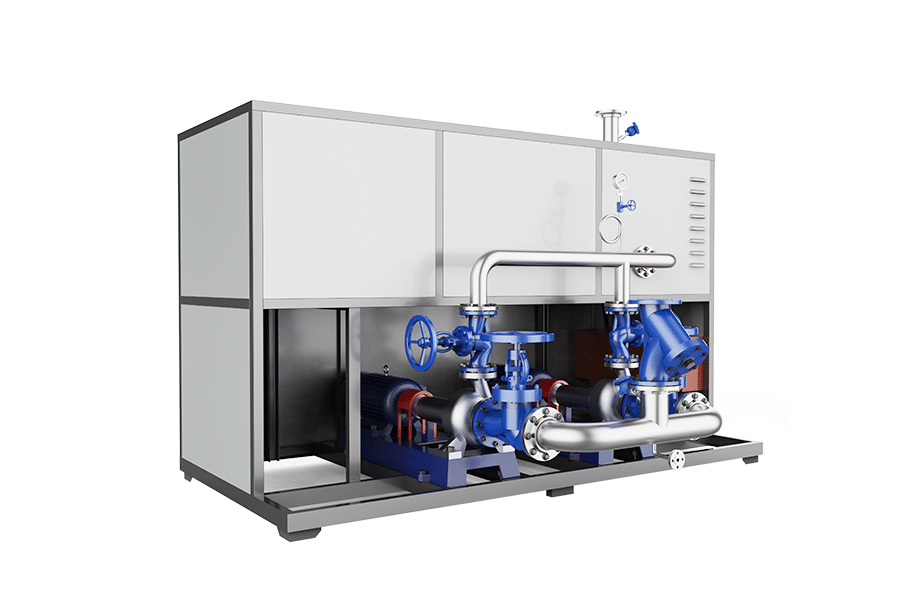

Product Overview

The electric heating thermal oil heaterhttps://8ruiyan.com/en/all-organic-heat-carrier-boilers/ is an energy-efficient heating device that uses electricity to heat thermal oil and delivers thermal energy to heat-consuming equipment through forced circulation by a high-temperature oil pump. As an important heating device in modern industrial production, electric heating thermal oil heaters are widely used in industries such as chemical, plastic, rubber, textile, and food processing due to their advantages of high efficiency, safety, and environmental friendliness.

Product Features of Electric Heating Thermal Oil Heaters

- High Efficiency & Energy Saving: Uses high-quality electric heating elements with a thermal efficiency of over 95%, saving 30%-50% more energy than traditional steam boilers.

- Точный контроль температуры: Equipped with an intelligent temperature control system, achieving a temperature accuracy of ±1°C to meet precise process requirements.

- Safe & Reliable: Multiple safety protection devices (over-temperature, over-pressure, oil shortage, leakage, etc.) ensure safe operation.

- Environmentally Friendly: No exhaust emissions, low noise, meeting modern environmental standards.

- Compact Structure: Modular design, small footprint, easy installation.

- Easy Operation: High automation level, capable of remote monitoring and operation.

- Long Service Life: High-quality materials and advanced manufacturing ensure a lifespan of 8-10 years under normal use.

Suitable Working Environment for Electric Heating Thermal Oil Heaters

- Altitude: Not exceeding 1,000 meters (special design required for higher altitudes).

- Relative Humidity: ≤90% (no condensation).

- Power Supply: 380V±10%, 50Hz three-phase five-wire system.

- Installation Site: Well-ventilated, dry, clean, and free from corrosive gases.

- Special Environments: Explosion-proof models required for hazardous areas.

- Applicable Industries:

- Chemical Industry: Reactor heating, distillation, and concentration.

- Plastics & Rubber: Calenders, internal mixers, vulcanizing machines.

- Textile & Dyeing: Heat setting machines, drying machines.

- Food & Pharmaceuticals: Sterilization, drying.

- Building Materials: Asphalt heating, concrete curing.

Working Principle of Electric Heating Thermal Oil Heaters

The working principle of electric heating thermal oil heaters is based on heat conduction and forced circulation:

- Heating Process: Electrical energy is converted into thermal energy via electric heating elements, heating the thermal oil.

- Circulation Process: A high-temperature oil pump forces the heated thermal oil to circulate to the heat-consuming equipment.

- Heat Exchange Process: The high-temperature thermal oil releases heat at the heat-consuming equipment and returns to the heater for reheating.

- Control System: Real-time monitoring and adjustment of system temperature via temperature sensors, PLC, etc.

- Protection System: Multi-parameter monitoring (pressure, flow, temperature) ensures system safety.

The system mainly consists of a heater, expansion tank, oil storage tank, circulation pump, filter, control system, and piping valves, forming a closed-loop circulation system.

Simulation Operation of Electric Heating Thermal Oil Heaters

Before formal startup, it is recommended to perform a simulation to familiarize yourself with the operation process:

- System Check Simulation

- Verify correct electrical connections.

- Ensure all valves are in the correct position.

- Check instrument displays for normal operation.

- Control Panel Operation Simulation

- Familiarize with button functions.

- Simulate temperature parameter settings.

- Understand alarm indicators.

- Fault Simulation & Handling

- Simulate over-temperature alarm and response.

- Simulate abnormal pressure and response.

- Simulate pump failure and response.

- Emergency Shutdown Simulation

- Locate the emergency stop button.

- Master the emergency shutdown procedure.

- Understand post-shutdown steps.

Heating & Operation Procedure for Electric Heating Thermal Oil Heaters

Pre-Startup Preparation

- Check all system connections for tightness.

- Ensure sufficient thermal oil with qualified quality.

- Inspect electrical system insulation.

- Confirm unobstructed circulation pipelines and correct valve positions.

Cold Startup Steps

- Open the expansion tank vent valve.

- Start the circulation pump and observe pressure and flow for normal operation.

- Confirm no system leakage before initiating low-power heating.

- Gradually increase temperature to working level (recommended heating rate ≤20°C/h).

Normal Operation Monitoring

- Regularly record system temperature and pressure.

- Observe circulation pump operation status.

- Check for abnormal noise or vibration.

- Monitor electrical system performance.

Normal Shutdown Procedure

- Gradually reduce heating power.

- Stop the circulation pump when oil temperature drops below 80°C.

- Turn off power and maintain operation records.

- Drain thermal oil if the system is to be idle for an extended period.

Inspection & Maintenance of Electric Heating Thermal Oil Heaters

Daily Inspections

- Daily Checks:

- Monitor system pressure and temperature.

- Check for leaks.

- Inspect electrical connections for overheating.

- Record operational parameters.

- Weekly Checks:

- Check expansion tank oil level.

- Clean control panel dust.

- Inspect pump seals.

- Test safety valve functionality.

Периодическое обслуживание

- Monthly Maintenance:

- Clean heater surface.

- Inspect terminal tightness.

- Test protection devices.

- Quarterly Maintenance:

- Replace or clean filters.

- Check thermal oil quality.

- Calibrate temperature and pressure instruments.

- Annual Overhaul:

- Full inspection of heating elements.

- Replace aged seals.

- Thorough system cleaning.

- Complete electrical system inspection.

Common Troubleshooting

- Heater Not Working:

- Check power supply.

- Verify thermostat settings.

- Inspect contactor status.

- Circulation Pump Failure:

- Check motor for overload.

- Inspect impeller for blockage.

- Check seals for leakage.

- Abnormal System Pressure:

- Check expansion tank oil level.

- Inspect pipelines for blockages.

- Verify thermal oil quality.

- Unstable Temperature Control:

- Check temperature sensor.

- Verify control parameter settings.

- Inspect heating elements for damage.

Заключение

The electric heating thermal oil heater, as an efficient and environmentally friendly heating device, plays an increasingly important role in modern industrial production. Correctly understanding its working principles, mastering standardized operation methods, and performing regular maintenance can ensure safe and stable operation, extend service life, and improve energy efficiency. Users should select appropriate models based on their production process requirements, strictly follow operating procedures, and conduct professional maintenance regularly to fully leverage the performance advantages of electric heating thermal oil heaters.

For technical inquiries, contact Ruiyuan’s official support team!

📞 📞 📞

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com