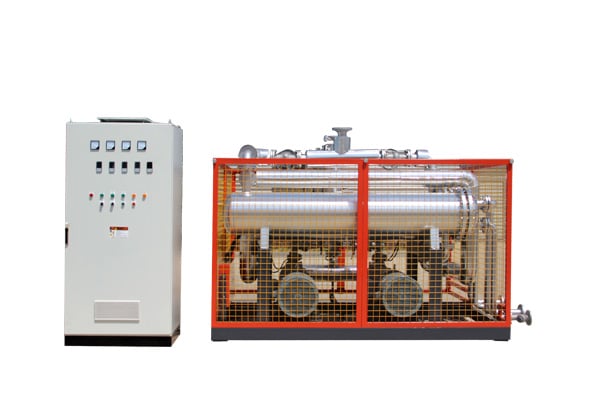

Heat transfer oil electric heatershttps://8ruiyan.com/en/all-organic-heat-carrier-boilers/ play a crucial role in many industrial applications, especially in processes requiring stable and uniform heat. They are widely used in industries such as chemical, food, pharmaceutical, plastics, and textiles. When selecting a heat transfer oil electric heater suitable for industrial use, multiple factors need to be considered comprehensively, including heating requirements, system stability, energy efficiency, and ease of maintenance. This article details how to choose an appropriate heat transfer oil electric heater for industrial applications.

I. Clarify Heating Requirements

The first step in selecting a heat transfer oil electric heater is to clearly define the heating system’s needs. Specific requirements include the following aspects:

- Heating Temperature Range:

- Different industrial processes require different heating temperatures. Heat transfer oil electric heaters are typically used for systems requiring higher temperatures, generally ranging from 150°C to 400°C. Therefore, select equipment appropriate for the required operating temperature.

- Crucially, the equipment’s maximum operating temperature should exceed the actual temperature needed during use to ensure safe operation.

- Heating Power:

- Determine the required heating power based on the flow rate of the heating medium, the temperature difference between inlet and outlet, and the required heating time.

- Insufficient heating power may lead to poor heating performance, while exceeding the power design can cause energy waste or equipment damage.

- Formula:

Q = m * C * ΔTQ: Required heating powerm: Mass flow rate of the fluidC: Specific heat capacity of the heat transfer oilΔT: Temperature change

- Heating Medium:

- The heating medium used in these heaters is typically heat transfer oil, making the selection of the right oil very important.

- Properties of the oil, such as thermal stability, viscosity, and thermal conductivity, affect heating efficiency and equipment lifespan.

- High-quality heat transfer oil can significantly improve heater efficiency and reduce the cost of frequent oil changes.

II. Equipment Type and Structural Design

- Heater Type:

- Based on the heating method, heat transfer oil electric heaters are mainly divided into two types:

- Immersion Heaters: These heaters place the heating elements directly into the heat transfer oil. They are typically suitable for systems with smaller oil volumes, featuring a simple structure and easy installation. Ideal for applications with limited space and small fluid volumes.

- Circulation/In-line Heaters: The electric heating elements in these heaters heat the oil as it flows through pipes or a pressure vessel. They are generally used for industrial systems requiring continuous heating of large oil flow rates. They offer higher thermal efficiency and are suitable for large-scale industrial heating systems.

- Based on the heating method, heat transfer oil electric heaters are mainly divided into two types:

- Heater Structure and Material:

- Consider the structural design and material of the heater during selection. Common materials include stainless steel and alloy steel, known for their good corrosion resistance and high-temperature tolerance.

- The surface design of the heater is also crucial; efficient heat conduction design can effectively improve heating efficiency and avoid heat waste.

- Control System:

- Modern heat transfer oil electric heaters are usually equipped with advanced temperature control systems, such as temperature controllers and automatic temperature regulators.

- These systems can automatically monitor temperature fluctuations during heating, maintain stable equipment temperature, prevent overheating or undercooling, and ensure smooth production processes.

- Choosing equipment with precise temperature control and automated management functions will significantly enhance system stability and safety.

III. Energy Efficiency and Environmental Friendliness

- Energy Efficiency Ratio (EER):

- The Energy Efficiency Ratio is a critical factor when selecting a heat transfer oil electric heater. Efficient heaters can reduce energy waste and lower production costs.

- Opt for high-efficiency electric heaters that deliver more heat output per unit of power consumed, thereby reducing energy consumption and improving production efficiency.

- Environmental Performance:

- In industries with high environmental requirements, choosing an environmentally friendly heat transfer oil electric heater is essential.

- The equipment should have good emission control systems to minimize environmental pollution.

- Additionally, selecting heat transfer oil with low pollution and low volatility is key to environmental protection.

IV. Safety

- Overheating Protection:

- The operating environment of heat transfer oil electric heaters is typically high-temperature, making equipment safety paramount.

- Ensure the electric heater has overheating protection devices that automatically cut off power if the system temperature becomes excessively high. This prevents equipment damage due to overheating and avoids safety accidents.

- Leakage Protection Design:

- As heat transfer oil electric heaters are electrical devices, leakage currents can cause equipment damage or electric shock accidents.

- Therefore, when selecting, ensure the equipment has comprehensive electrical safety protection designs, such as leakage protection (RCDs/GFCI), grounding protection, etc.

- Regular Inspection and Maintenance Features:

- Choosing equipment designed for easy maintenance is crucial for ensuring safety. Regular checks of the heater’s operating status are vital.

- Equipment should have designs that prevent contaminants from entering, reducing damage caused by impurities in the heat transfer oil.

- Good maintenance access and cleaning designs also ensure long-term stable operation.

V. After-Sales Service and Support

Heat transfer oil electric heaters are efficient and critical industrial equipment. When choosing, consider the supplier’s after-sales service and technical support. A reliable supplier should provide:

- Detailed installation guidance, commissioning services, regular maintenance, and troubleshooting to ensure the equipment remains stable during long-term operation.

- Warranty Period and Repair Service:

- Generally, heat transfer oil electric heaters should come with a warranty of at least 1-2 years.

- During the warranty period, the supplier should provide free repairs and replacement of parts.

- Furthermore, choose suppliers with a quick after-sales response and a well-established service network to resolve problems promptly when they arise.

- Technical Support and Training:

- Technical support is equally important when selecting a heater.

- Suppliers should provide relevant operational training so that personnel can master equipment operation methods and maintenance skills, avoiding malfunctions caused by improper operation.

VI. Summary

Selecting a heat transfer oil electric heater suitable for industrial use requires comprehensive consideration of multiple factors: heating requirements, equipment type, energy efficiency, environmental friendliness, safety, and after-sales service.

Choosing the right equipment can improve heating efficiency, reduce operating costs, and extend the equipment’s service life. For large industrial systems, selecting an efficient, safe, and easy-to-maintain heat transfer oil electric heater not only enhances production efficiency but also effectively ensures the stability and safety of the production process.

For further consultation, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:nieyili@cnryan.com