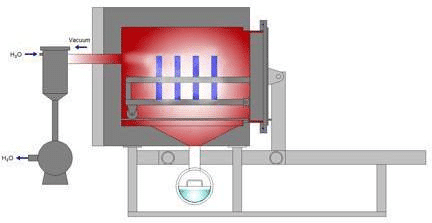

If you’ve ever worked with or around vacuum furnaces https://8ruiyan.com/en/all-vacuum-cleaning-furnaces/, you’ve likely heard about the spray system — sometimes called the “quench spray” or “dust suppression spray.” At first glance, it’s easy to assume its purpose is cleaning: after all, there’s water spraying inside a furnace, so it must be for washing off dust or debris from the parts, right?

That’s a common and understandable misconception. In reality, the spray system plays a very different — and crucial — role in furnace performance and longevity.

So, what is it really for?

The spray system is essentially a dust control and vacuum pump protection system. It’s designed not to clean your workpiece, but to protect your furnace’s internal components and the expensive vacuum pump from damage caused by fine particulate contamination.

How It Actually Works (Step by Step)

- Dust Generation

During high-temperature cycles — especially during heating, cooling, or certain metallurgical processes — microscopic dust, soot, and fine particles can form inside the chamber. This is normal, but problematic if left unchecked. - Exhaust Flow

These particles are carried by the airflow toward the exhaust line, on their way to the vacuum pump. - Spray Activation

The spray system injects a controlled, fine mist of water (sometimes with additives) into the exhaust stream — not into the main chamber where the parts are. - Dust Capture

Water droplets collide with the dry dust particles, absorbing and weighting them down. The dust becomes damp and agglomerates into heavier clusters. - Separation

These wet clusters are too heavy to remain airborne. They drop out of the airflow or collect in a separator, preventing them from ever reaching the vacuum pump.

Why This Matters

- Pump Protection: Vacuum pumps are precision instruments. Dry dust can cause abrasion, clog filters, and degrade oil, leading to costly repairs and downtime.

- System Longevity: Cleaner exhaust means less maintenance, longer intervals between servicing, and more consistent furnace performance.

- Safety & Efficiency: Wet dust is easier and safer to handle and dispose of compared to dry, airborne particles.

Common Myths vs. Facts

| Myth | Fact |

|---|---|

| The spray cleans the parts after processing. | The spray never touches the parts; it acts only in the exhaust line. |

| It’s only needed during quenching. | It can operate during various stages to control dust continuously. |

| Plain water is always used. | Sometimes additives are used to improve wetting or corrosion resistance. |

Maintenance Tip

Regularly check the spray nozzles for clogging and the water supply for consistency. A malfunctioning spray system can silently put your vacuum pump at risk.

In a Nutshell

- ❌ Not for: Cleaning parts or improving surface finish.

- ✅ Actually for: Capturing dust in the exhaust to protect the vacuum pump and enhance system reliability.

Understanding this key function helps operators maintain their equipment better, avoid unnecessary downtime, and extend the life of their vacuum furnace investment.

Have questions or experiences to share about furnace spray systems? Drop a comment below — let’s keep the conversation going.

For further problems about the spray system, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com