Imagine your thermal fluid heater as the heart of your industrial heating process. It pumps heat through your system, much like blood circulates through veins. But what happens when gas bubbles form in that vital flow? Just as air in a bloodstream can cause serious problems, gas in a thermal oil system can lead to inefficiency, damage, and even danger.This is where the oil-gas separator https://8ruiyan.com/en/all-organic-heat-carrier-boilers/ steps in—a seemingly simple vessel that performs a lifesaving role. Often overlooked, this component is a fundamental pillar of safety, efficiency, and longevity for your entire heating system.

What Exactly Is an Oil-Gas Separator?

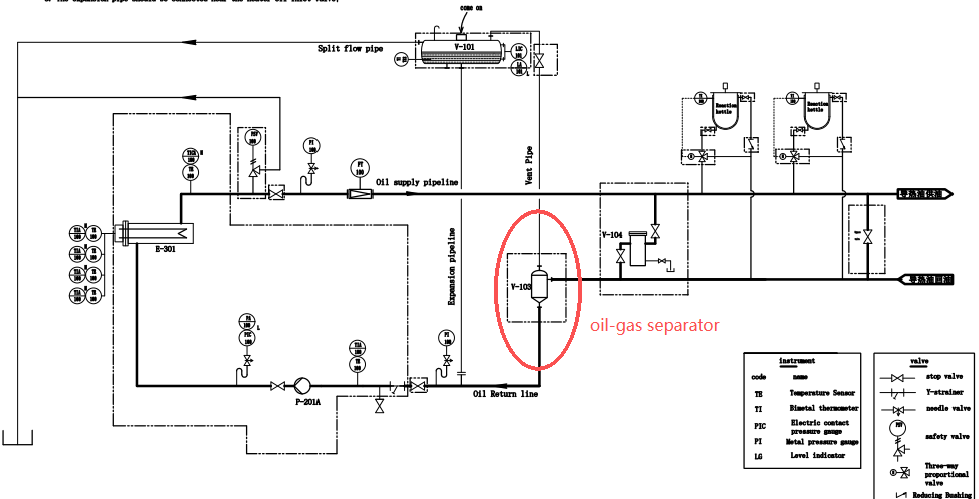

At its core, it is a dedicated tank installed on the discharge side of the heater, before the circulation pump. Its primary mission is to provide a calm, expanded space for the hot thermal fluid. Here, the fluid’s velocity drops, allowing for a natural and crucial separation: the dense liquid oil settles, while any entrained vapors or light gases rise to the top.

Why Can’t Your System Live Without It?

The importance of this separation cannot be overstated. Here are the key reasons this tank is indispensable:

- Pump Protector: Guarding the Heart of the System

The circulation pump is the engine of your thermal fluid loop. It is designed to move incompressible liquids efficiently. When gas or vapor enters the pump, it causes cavitation—the formation and violent collapse of air bubbles. This leads to loud knocking noises, reduced flow, erosion of impeller surfaces, and ultimately, pump failure. The separator acts as a reliable bouncer, ensuring only liquid enters the pump, thereby extending its service life dramatically. - System Stabilizer: Ensuring Smooth and Consistent Operation

Gas pockets within the piping are troublemakers. They create erratic flow, cause unpredictable pressure spikes, and lead to uneven heating at your process points. This inconsistency can ruin product quality in sensitive applications. By systematically removing these gases, the separator guarantees a steady, predictable, and smooth flow of heat, which is the foundation of precise thermal control. - Safety Sentinel: Providing a Critical Pressure Relief Path

This is perhaps its most vital function. The top of the separator is connected directly to the expansion tank via an open vent line. This line is the system’s designated “breathing apparatus.” It provides a safe, controlled escape route for:- Volatile vapors released from the fluid during high-temperature operation.

- Air released from the fluid after system startup.

- Excess volume from the expanding hot oil.

By offering this direct path, the separator prevents dangerous pressure buildup within the active heater and piping, forming a cornerstone of the system’s inherent safety design.

- Efficiency Keeper: Maintaining Optimal Heat Transfer

Gas is an excellent insulator. The presence of gas films or bubbles on the heater’s heat transfer surfaces or in the user equipment creates a barrier, drastically reducing heating efficiency. This forces the system to work harder and consume more fuel. A well-functioning separator maintains the fluid’s liquid state, ensuring maximum contact with heat exchange surfaces for superior energy efficiency.

In Conclusion: The Unassuming Guardian

The oil-gas separator is a masterclass in elegant engineering—achieving profound results through simple principles. It requires no moving parts, no external power, and minimal maintenance, yet it tirelessly performs the essential tasks of separation, stabilization, protection, and safety assurance.

Investing attention in this component—ensuring it is correctly sized, properly installed, and regularly maintained—is not an option; it is a necessity. It directly protects your capital investment in the pump and heater, safeguards your operational continuity, and upholds the safety of your plant and personnel.

Never underestimate this humble tank. In the complex orchestra of a thermal fluid system, the oil-gas separator is the silent conductor, ensuring everything flows in harmony.

For further problems about organic thermal fluid heaters, please contact our technical team for expert advice.

Whatsapp:86-19106101570

wechat:86-19106101570

email:fob@jsryan.com