Flange heater as a widely used in industrial heating equipment, its selection needs to be combined with the actual application requirements, environmental conditions and technical parameters and other factors. This article will focus on how to choose the right flange heater to help users make a more informed choice.

Determination of heating power

The power of the flange heater directly affects its heating efficiency and effect. Different application scenarios have different heating power requirements, and the selection should be based on the volume of the medium to be heated, temperature requirements and environmental conditions to determine the power. For example, for large-volume liquid heating or application scenarios requiring higher temperatures, it is recommended to choose a flange heater with higher power to ensure uniformity and stability of heating.

Choosing the right material

The material selection of flange heater should consider the corrosiveness of the medium to be heated and the temperature conditions of the working environment. Commonly used materials include stainless steel, carbon steel and titanium alloy, etc. Among them, stainless steel is suitable for heating a variety of liquid and gaseous media, while titanium alloy is more suitable for highly corrosive media. Choosing the right material helps to extend the service life of the flange heater and improve its corrosion resistance and stability.

Attention to temperature control accuracy

Different application scenarios have different requirements for temperature control accuracy. For chemical or food processing industries with strict temperature requirements, it is recommended to choose flange heaters with precise temperature control function. This kind of equipment is usually equipped with advanced temperature control system, which can realise the fine adjustment of temperature, so as to ensure the stability and safety of the processing.

Consider installation requirements

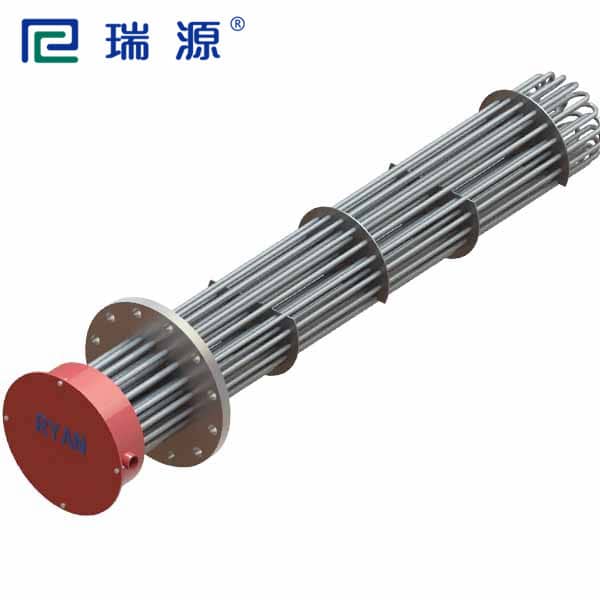

Installation space and interface methods are also important considerations when selecting a flange heater. Flange heaters usually require a large installation space, and the size of the equipment should be determined according to the space available at the installation location. In addition, the interface method should also match the existing equipment interface for smooth installation and connection to improve work efficiency.

Assessing the special needs of the environment in which it will be used

Some special environments place higher durability requirements on flange heaters, such as high humidity, high temperature or highly corrosive environments. In this case, it is recommended to choose flange heaters that have been specially treated or have a design that is resistant to high temperatures and high corrosiveness to ensure the stability and safety of the equipment.

in summary ...The selection of suitable flange heaters requires comprehensive consideration of factors such as power, material, temperature control precision, installation requirements and the use of the environment. Reasonable choice of suitable flange heater can not only enhance the efficiency of the equipment, but also effectively extend the service life. The company can be non-standard custom flange heater, click the menu bar to contact us to customise, you can also refer to the product page to appreciate the company's products!

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading:

Main Advantages of Flange Heaters - Jiangsu Ruiyuan Heating Equipment Technology Co.