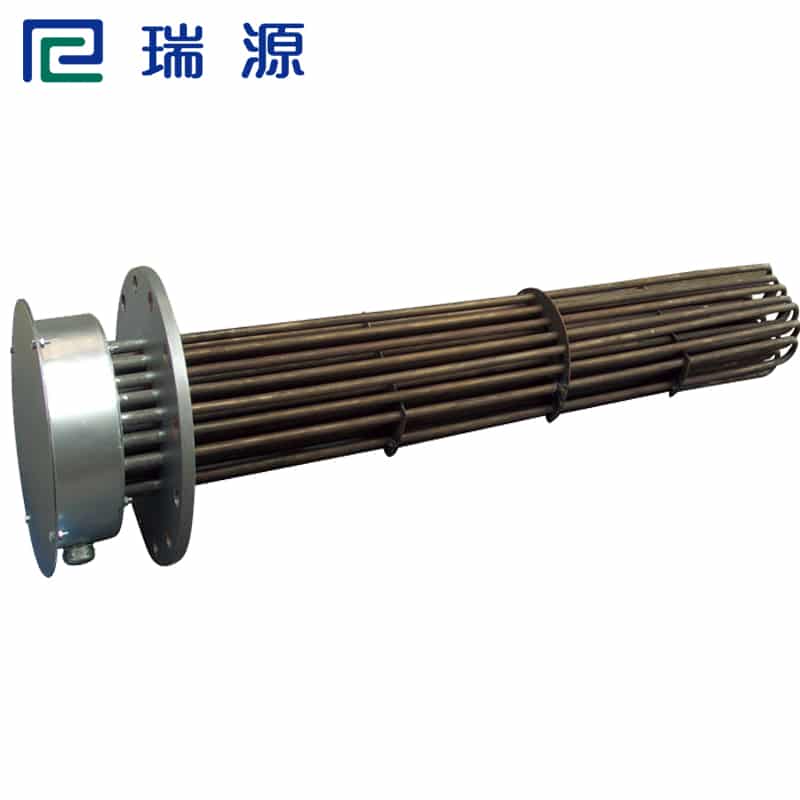

As an efficient industrial heating equipment, the power and energy efficiency of flange heaters are important indicators for assessing their performance. In practical application, the reasonable selection and use of flange heater power can not only ensure the heating effect, but also maximise energy saving and consumption reduction. The power and energy efficiency of flange heaters will be discussed in detail below.

1. Power requirements for flange heaters

The power of the flange heater is closely related to the use scene and heating medium of the equipment. When choosing a flange heater, the first thing to consider is the heat load demand of the object to be heated and the environment. Too low a power may lead to poor heating effect and fail to meet the production demand, while too high a power may lead to energy waste and increase the operation cost. Therefore, determining the appropriate power is the basis for ensuring the efficient operation of the heater.

Usually, the power range of flange heaters can be adjusted according to the temperature demand of the heating medium, and the common heater power ranges from a few kilowatts to tens of kilowatts. When choosing, in addition to considering the environment and temperature requirements, it is also necessary to comprehensively consider the working efficiency, durability and reliability of the equipment.

2. Energy efficiency performance of flange heaters

The energy efficiency of a flange heater is mainly related to its heating method, heating material and design process. Excellent flange heaters can achieve high thermal conversion efficiency and minimise energy consumption. The energy efficiency of the heater is closely related to its design structure, especially the control of heat loss and heat transfer efficiency.

Modern flange heaters use highly efficient electric heating materials and advanced temperature control technology, which results in a higher utilisation of heat energy in the heating process. When choosing a flange heater, you can compare the energy efficiency ratings of different brands and models and choose those with higher energy efficiency ratios to reduce energy costs in long-term use.

3. High-efficiency flange heater features

High-performance flange heaters typically have several features:

- accurate temperature control: Through the advanced temperature control system, the flange heater is able to precisely regulate the heating temperature to avoid unnecessary waste of heat energy.

- Rapid warming: Efficient heaters reach the set temperature in a short period of time, reducing heating time and further saving energy.

- heat evenly: The heater is well designed to provide even heat distribution, reducing localised overheating and energy wastage.

- Durable: Manufactured from high-temperature resistant, high-efficiency materials to reduce energy efficiency degradation due to aging or damage to equipment.

4. Energy efficiency and environmental protection

With rising energy costs and environmental awareness, energy saving and environmental protection have become important goals in flange heater design. Choosing a high-efficiency flange heater not only helps to reduce energy costs, but also reduces greenhouse gas emissions, which meets the requirements of modern industry for sustainable development.

summaries: The economy and environmental friendliness of flange heaters can be greatly improved by choosing the power reasonably and focusing on the improvement of energy efficiency. When shopping for flange heaters, users should consider heating needs and energy costs, and choose high-efficiency flange heaters to ensure the best use experience.

Our company can non-standard custom products, click the menu bar to contact us to customise, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading:

Flange heater suitable for which heating medium? - Jiangsu Ruiyuan Heating Equipment Technology Co.