Quality first, non-standard customisation

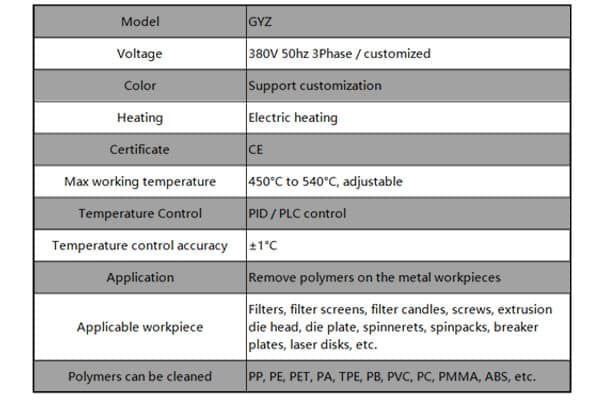

Industrial spinneret cleaning machine ultrasonic polyester spinneret cleaning machine

Products

Working Principle

Ultrasonic Cleaner

The use of ultrasonic cavitation effect, so that the cleaning fluid in the expansion of tiny bubbles rupture impact, while the direct flow to promote the flow of cleaning fluid, acceleration to promote particle impact, the three synergistic effect, the destruction of die dirt and die head adsorption, stripping and removal of dirt, to achieve the effect of precision cleaning.

Product Details

Cleaning Tank:Cylinder made of stainless steel cylindrical body, the cylinder is filled with triethylene glycol (TEG) solution. Cylinder outside the cooling jacket, used to cool the temperature of the three glycol solution after the end of the cleaning, cooling jacket and the furnace body is filled with insulation cotton between the outer cladding. The cylinder is equipped with a heater installation port, waste discharge port and jacket cooling water inlet and outlet.

Cover and condenser:The furnace cover and condenser are made of stainless steel. Cooling water is passed through the condenser to condense the vaporised triethylene glycol, so that the condensed triethylene glycol flows back to the cleaning tank, and a small portion of the vaporised water flows into the built-in secondary condensation recycling device. Therefore, it not only reduces the consumption of triethylene glycol, but also eliminates the environmental pollution and ensures the safe working conditions of atmospheric pressure and high temperature.

Electrically heated section:The flanged stainless steel heater is inserted directly into the triethylene glycol solution for heating, using the "Y" connection.

Hanging baskets:Used to contain the parts to be cleaned. Special requirements can be designed and manufactured on behalf of the company.

Control section:The temperature is controlled automatically by Japanese "Fuji" temperature controller. The main circuit is controlled by solid state relay with over-temperature alarm function, and the working time is regulated and controlled by time relay, as long as the proposed working procedure is inputted into the instrument, the equipment can work automatically without manual intervention, and it will be shut down automatically at the end of the working procedure.

Cleaning process:The parts which are stained with chemical fibre polymer are placed in a hanging basket and put into the cleaning tank before the triethylene glycol solution is at room temperature or warmed up to 100°C. The parts are cleaned by opening the condensation tower and boiling for a number of hours. Continue to raise the temperature, and open the condensation tower with cooling water, so that the cleaned parts in the cleaning tank boiling for a number of hours, to be cooled to 100 ℃, open the lid of the furnace, lifting out the cleaned parts.

Product Advantage

Quality first

quality assurance (QA)

Strict quality control ensures that the quality meets the standard and enhances customer satisfaction.

quality control

rigorous standard

Equipped with the Special Inspection Institute on-site personnel, the equipment factory have been strictly inspected.

Expertise

Precision and Meticulousness

Rigorous welding, precision and meticulous, seamless welding, fine workmanship and exquisite.

Cleaning effect

Product Advantage

Precise temperature control and cleanliness

Professional After Sales

factory direct

quality assurance

craftsmanship

principal

Applicable industries

01

Injection moulding and extrusion process

02

Plastic recycling

03

chemical fibre industry

03

Nonwoven Meltblown Fabric Industry

Live Cases

Quality first

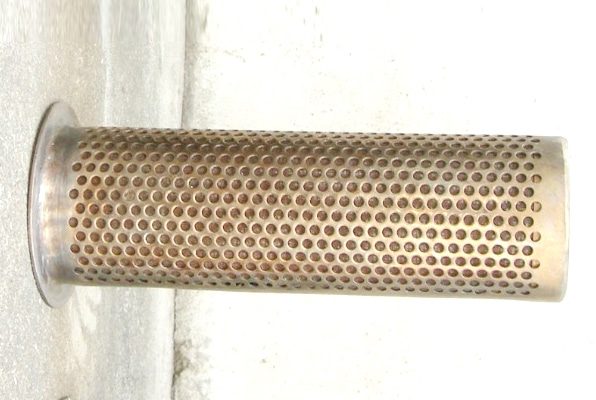

Excellent cleaning effect

Such as polymer residues on the spinneret, etc., so that the cleaned parts plate surface is clean, the silk hole is smooth, and good performance is restored.

Quality first

energy-saving and efficient

Short working time and low energy consumption can reduce the operating costs of enterprises, and at the same time, the shorter cleaning cycle also helps to improve the production efficiency.

Quality first

Reliable equipment performance

Equipped with advanced temperature control system, it can precisely adjust the heating rate and maintain constant temperature.

Quality first

High degree of automation

Easy operation reduces labour intensity, improves productivity and also reduces human error.

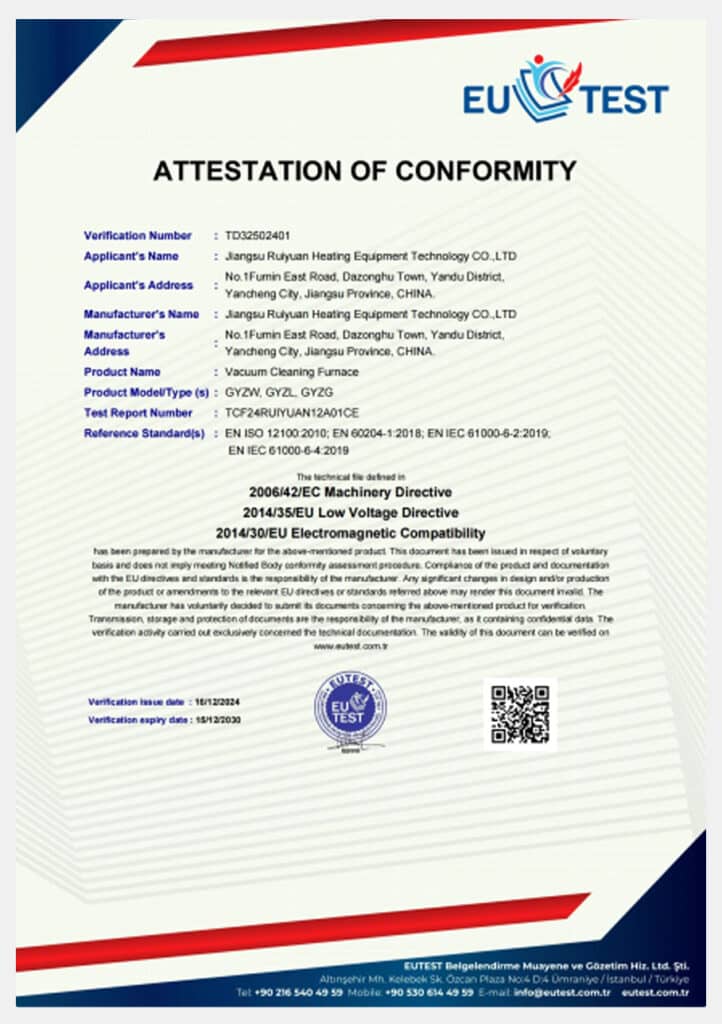

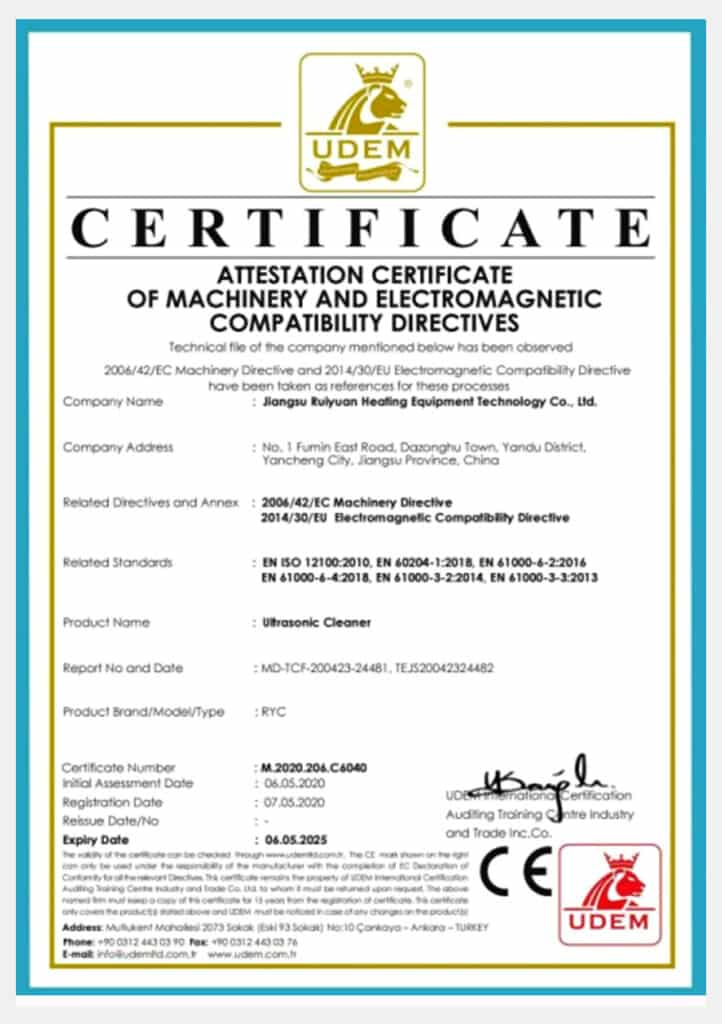

Complete qualification, reliable quality