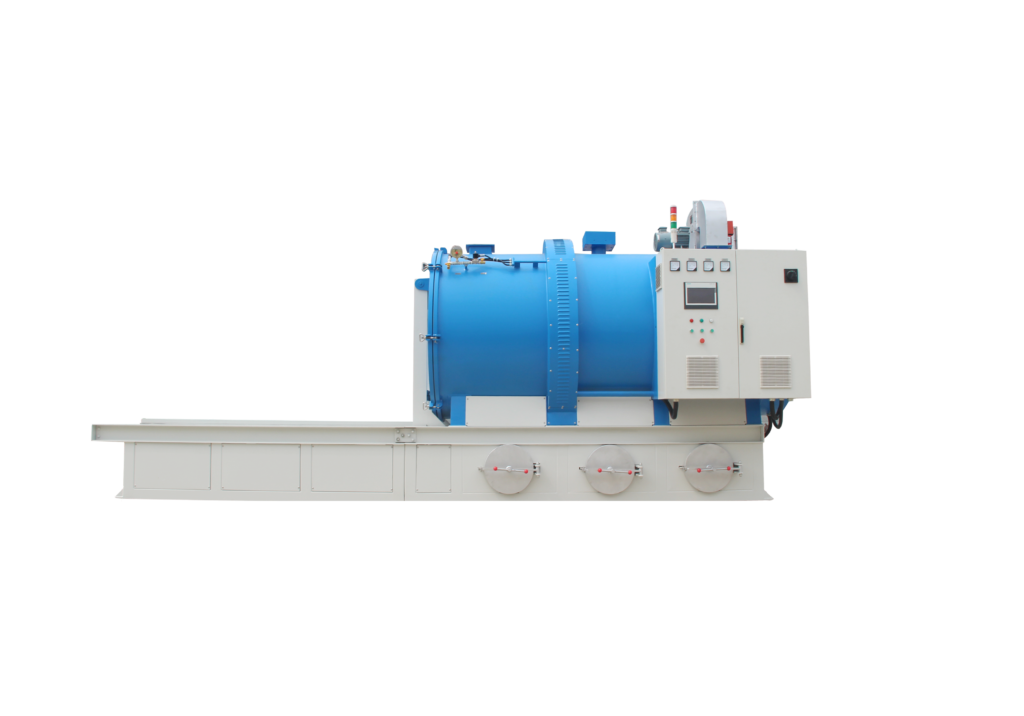

Vacuum cleaning furnace is a kind of efficient cleaning device commonly used for cleaning precision parts and industrial equipment. In order to ensure that the cleaning effect and extend the life of the equipment, the use of vacuum cleaning furnace need to pay attention to a series of operating specifications, to avoid common misuse. Jiangsu Ruiyuan heating equipment technology company for you to sum up the use of vacuum cleaning furnace of the main points of attention to help you improve the cleaning efficiency while ensuring the safe operation of the equipment.

1. Preheating operations should not be neglected

Before formal use of the vacuum cleaning oven, preheating is recommended to ensure that the oven reaches the required operating temperature. The preheating operation not only helps to improve the cleaning effect, but also reduces the surface damage of the workpiece caused by temperature difference. Usually, depending on the type of equipment and the material of the cleaned items, the preheating time is kept from a few minutes to ten minutes.

2. Reasonable arrangement of items to be cleaned

During the cleaning process, make sure that the items to be cleaned are evenly distributed in the chamber to avoid overlapping or clogging. Uniform placement allows the cleaning medium and temperature to act fully on the surface of each workpiece, avoiding poor localised cleaning results.

3. Control of temperature and time

Vacuum cleaning ovens usually need to work in a high-temperature environment, but workpieces made of different materials have different temperature tolerances. Therefore, it is particularly important to set the right temperature and cleaning time. Too high a temperature may cause damage to the workpiece, while too low a temperature may affect the cleaning results. It is usually recommended to operate within the temperature range provided by the manufacturer to ensure cleaning efficiency and workpiece safety.

4. Regularly check the vacuum status

The vacuum condition is essential to ensure that the cleaning oven works efficiently. Before each use, it is recommended to check the vacuum status of the unit to ensure that it is able to provide sufficient negative pressure to support a smooth cleaning process. If insufficient vacuum is found, timely maintenance should be carried out to check whether the sealing system and pump are functioning properly.

5. Cooling treatment after cleaning

After the vacuum cleaning furnace cleaning is completed, the workpiece needs to be allowed to cool gradually in the furnace to prevent material stress damage caused by sudden cooling. Taking out the workpiece too quickly may lead to too large a temperature difference, triggering surface cracking or deformation. Therefore, it is appropriate to take out the workpiece after the temperature inside the furnace has gradually dropped to a safe range.

Our company can non-standard custom products, click the menu barContact UsReady to customise or refer to firstproduct pageAppreciate our company's products oh!

Recommended Reading:

Fluidised cleaning bed how to clean the workpiece? -Ideal for Enhancing Industrial Cleaning Efficiency - Jiangsu Ruiyuan Heating Equipment Technology Co.