Quality first, non-standard customisation

Vacuum Cleaning Furnaces for the Film Industry

Products

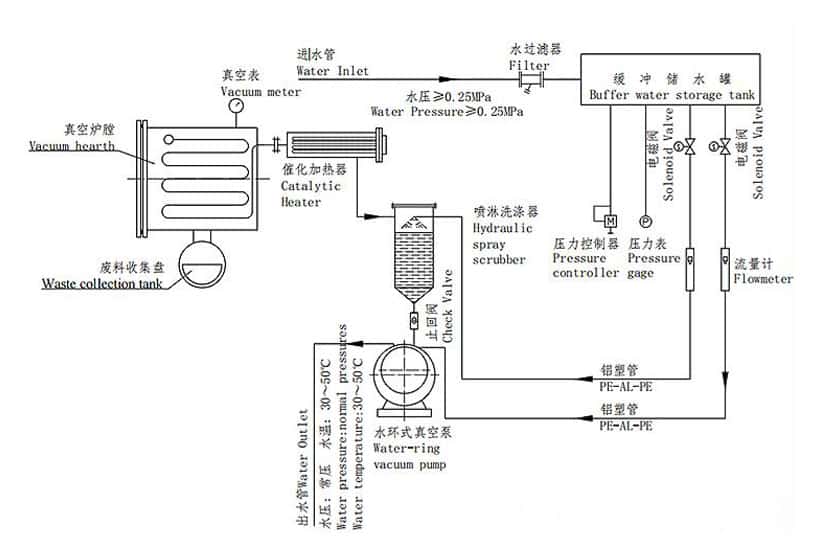

Working Principle

Vacuum Cleaning Furnace

The vacuum cleaning oven uses an electrically heated vacuum cleaning chamber for fully automatic cleaning. The temperature is measured directly on the product during operation. The product is initially heated slowly and gently, during which a large portion of the adhering polymer starts to melt and flow down. Once the temperature reaches approximately 450°C, the rest of the polymer begins to decompose and the remaining carbon is finally removed by the addition of air (oxidation). A precise sensor controls the cleaning process, ensuring that the temperature is not too high at any time. Inorganic residues can be easily removed in post-processing (e.g. using compressed air, ultrasound).

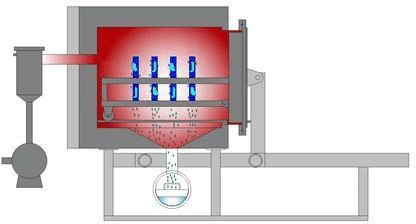

I. Melting Phase

The parts to be cleaned are heated to 320°C in the chamber. After this process, most of the polymer melts and drains into the bottom collector

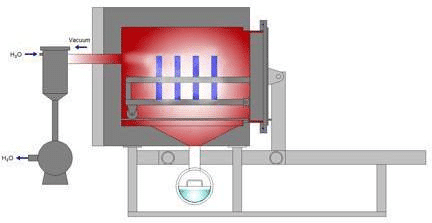

II. Pyrolysis Phase

Polymer that did not melt during the first phase will be pyrolyzed and vaporised under vacuum. The generated gases are then water scrubbed in a secondary scrubber where condensates are collected and rushed out with water. The generated gases are then water scrubbed in a secondary scrubber where condensates are collected and rush out with water.

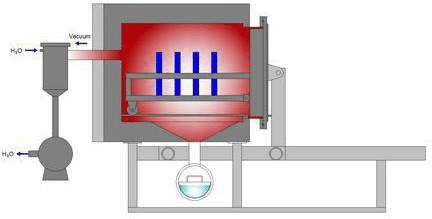

III. Oxidation Phase

Remaining polymer that still exists after the pyrolysis phase will be burnt under vacuum and limited air.

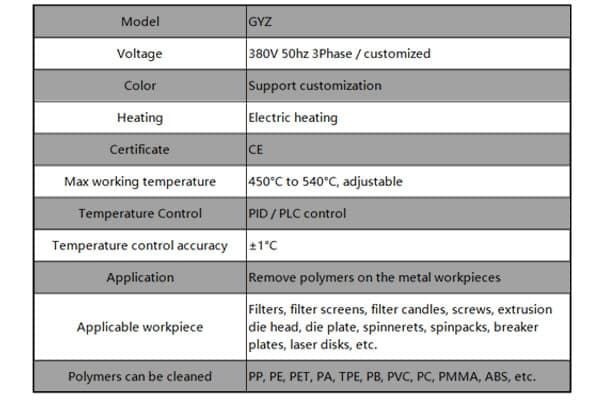

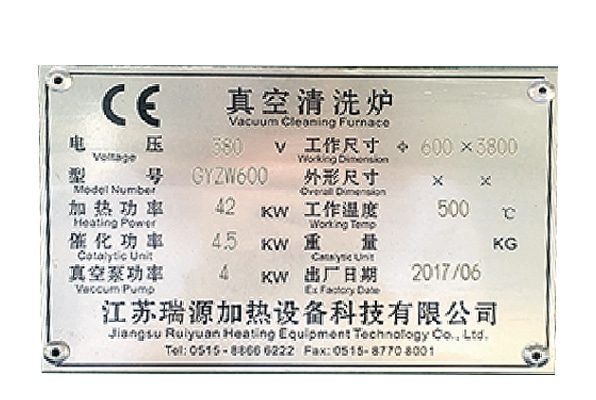

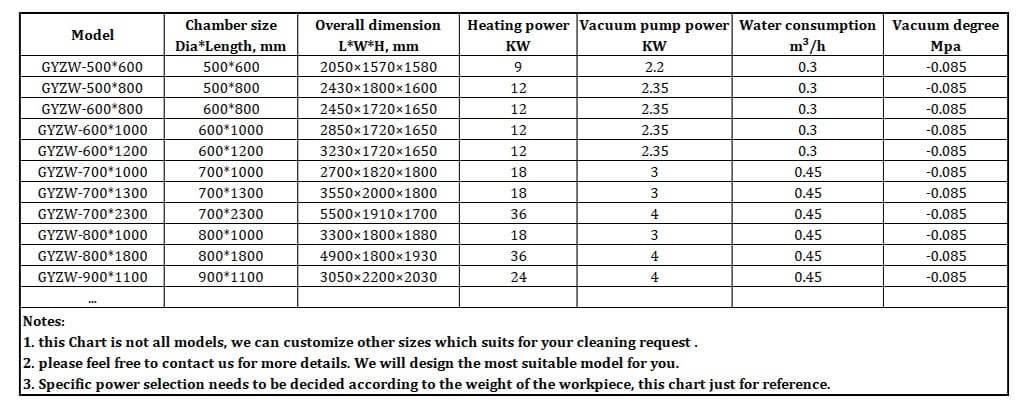

Technical parameters

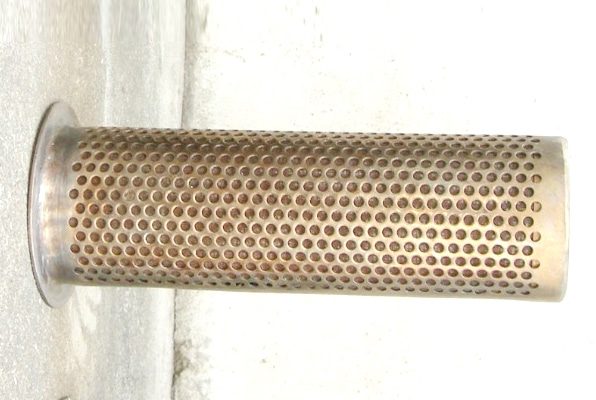

Product Accessories

Product Parameter

Clear specifications and understanding of the product

1

Vacuum furnace chamber

2

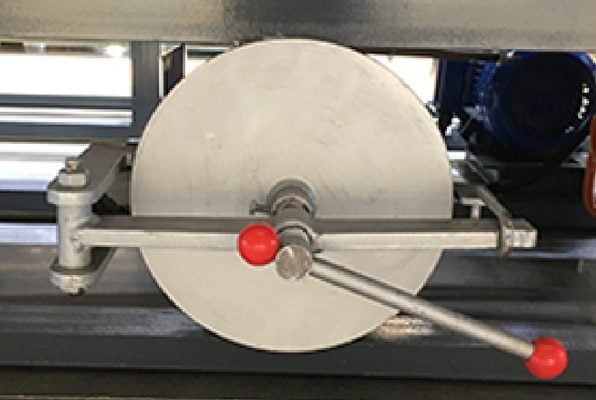

Furnace opening seal

3

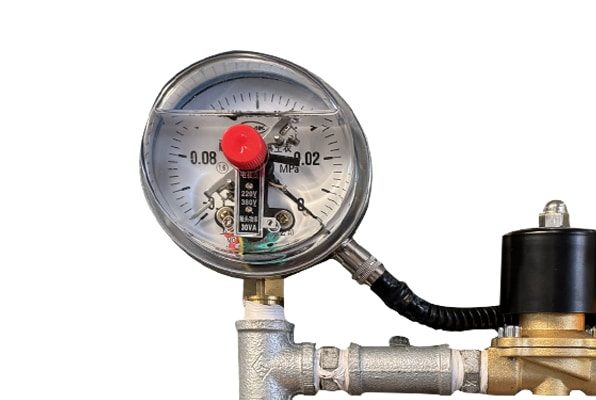

vacuum gauge

4

control cabinets

5

Waste collection tank

6

vacuum pumps

7

Secondary high temperature calcination

Cleaning effect

Product Advantage

Precise temperature control and cleanliness

Live Cases

Quality first

Excellent cleaning effect

Such as polymer residues on the spinneret, etc., so that the cleaned parts plate surface is clean, the silk hole is smooth, and good performance is restored.

Quality first

energy-saving and efficient

Short working time and low energy consumption can reduce the operating costs of enterprises, and at the same time, the shorter cleaning cycle also helps to improve the production efficiency.

Quality first

Reliable equipment performance

Equipped with advanced temperature control system, it can precisely adjust the heating rate and maintain constant temperature.

Quality first

High degree of automation

Easy operation reduces labour intensity, improves productivity and also reduces human error.

Professional After Sales

factory direct

quality assurance

craftsmanship

part

Applicable industries

01

Injection moulding and extrusion process

02

Plastic recycling

03

chemical fibre industry

03

Nonwoven Meltblown Fabric Industry

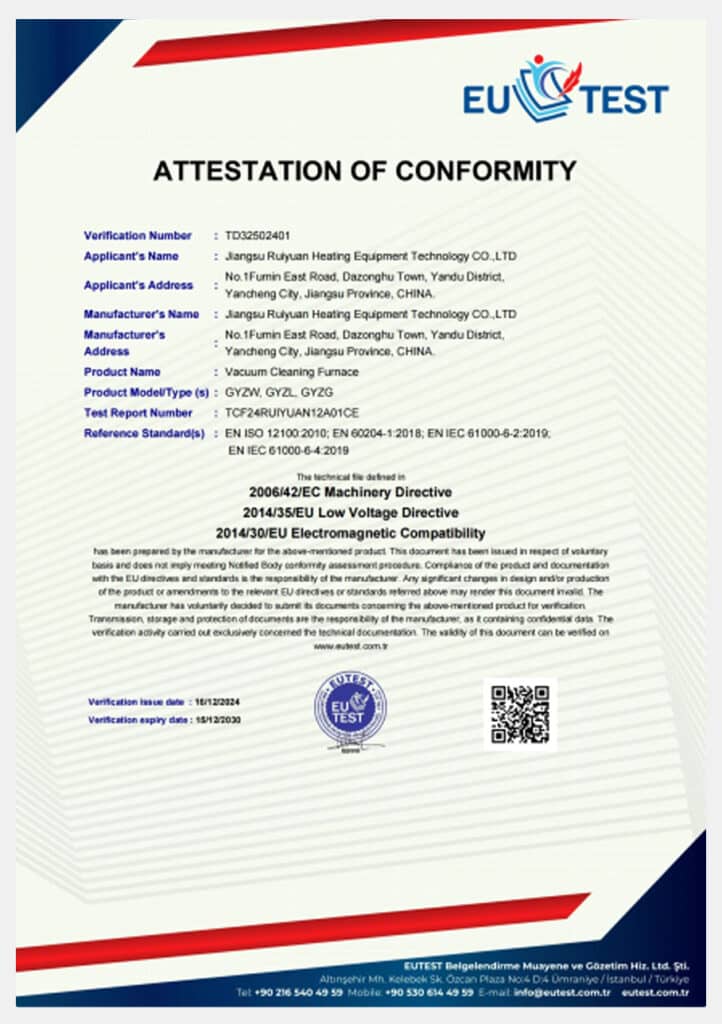

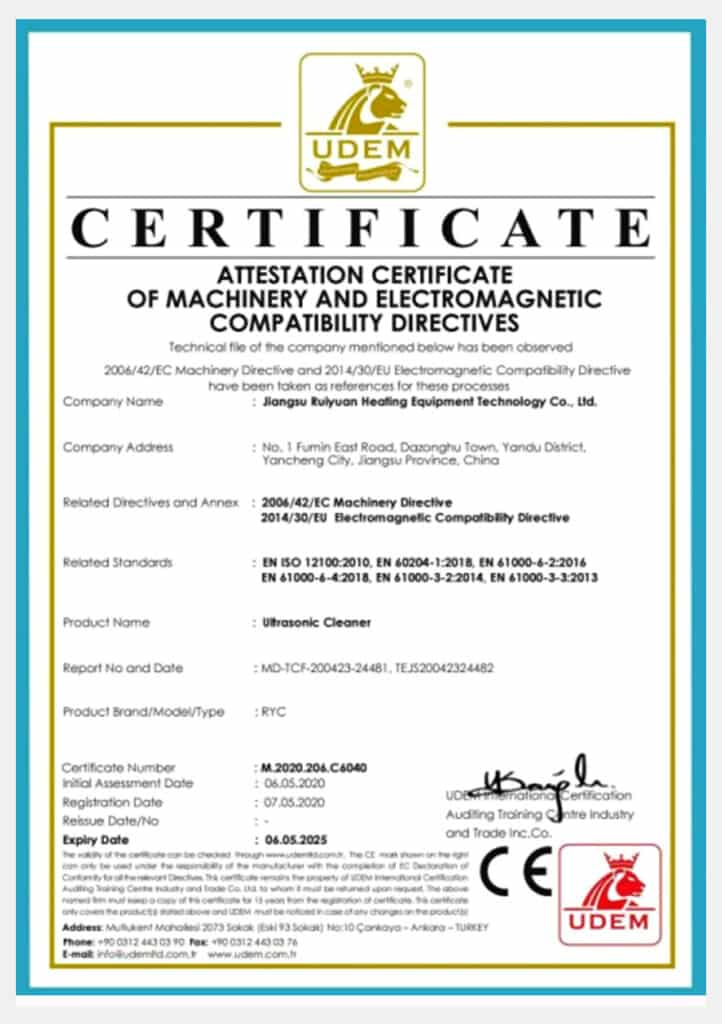

Complete qualification, reliable quality