In industrial production, many processing and manufacturing processes require efficient and stable high temperature heating systems. Thermal Oil Boilers, as an advanced industrial heating equipment, use organic liquids (such as thermal oil) as heat carriers to provide safe and stable high-temperature heating services for many industries, such as petrochemical, food processing, pharmaceuticals and so on. This article will provide an in-depth analysis of what is an Thermal Oil Boiler, its working principle, advantages and its wide range of applications.

I. Definition of Thermal Oil Boiler

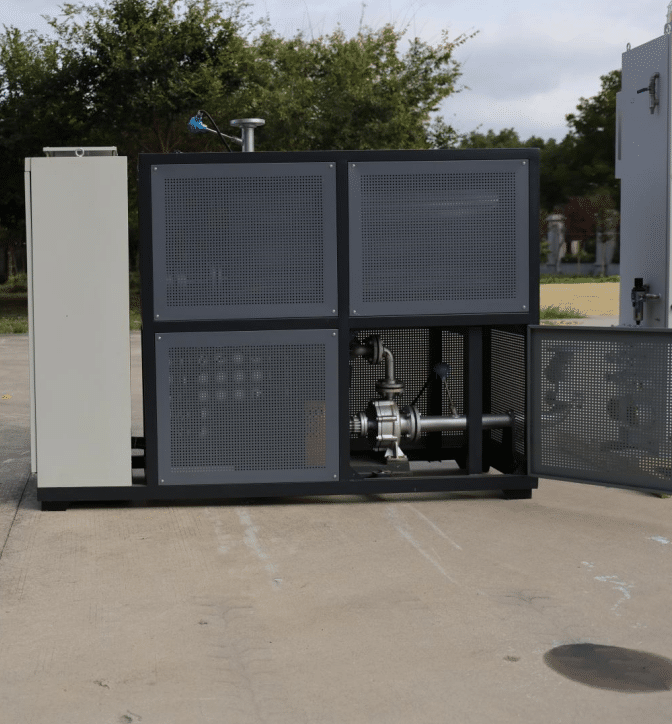

Thermal Oil Boilers, often also referred to as thermal oil boilers, are a type of boiler system that utilises an organic liquid, such as thermal oil, to circulate heat in a closed loop. Unlike conventional steam boilers, Thermal Oil Boilers can provide high temperatures at lower pressures, typically up to 300°C to 350°C, making them suitable for industrial environments that require consistently high temperatures.

Second, the working principle of Thermal Oil Boiler

The Thermal Oil Boiler heats the thermal oil to a set temperature by means of a combustion system, and then uses a circulation pump to transfer the heated thermal oil to the heat exchanger or production equipment. The heat transfer oil transfers heat to the material or production equipment in the equipment and then returns to the boiler to be heated again. The whole process is carried out in a closed-loop system, realising effective heat recycling and precise temperature control.

Third, the main advantages of Thermal Oil Boiler

- high temperature, low pressure

Compared with conventional steam boilers, Thermal Oil Boilers are able to achieve high temperature output at low pressure. It typically operates at pressures below 1MPa, but can deliver high temperatures of over 300°C, ensuring a safe and efficient production process. - Precise temperature control

Thermal Oil Boilers are equipped with a precise temperature control system that can control the temperature within a range of ±1℃. This precise temperature control is ideal for processes that require constant temperature heating to ensure product quality. - high efficiency and energy saving

Heat transfer oil has excellent thermal conductivity and can reach high temperatures in a relatively short period of time while maintaining a stable temperature. In addition, the closed-loop circulation system enables the heat to be reused, reducing energy consumption and achieving energy saving and environmental protection. - Wide range of applicability

Thermal Oil Boilers are suitable for a wide range of industrial production scenarios, including chemical, pharmaceutical, building materials, food processing and other industries, and are particularly suitable for heating processes that require long periods of continuous operation.

Fourth, the application areas of Thermal Oil Boiler

- petrochemicals

In the petrochemical industry, Thermal Oil Boilers are commonly used to heat high-temperature reactors, distillation towers and other equipment to ensure stable reaction and efficient extraction of raw materials. - food processing

The food processing industry requires a stable high-temperature environment, for example, in frying, baking and drying processes, where the precise temperature control of an Thermal Oil Boiler ensures the quality and taste of the processed food. - pharmaceutical industry

Pharmaceutical processes often involve high-temperature drying and extraction processes, Thermal Oil Boilers provide a stable high-temperature environment to ensure the purity and quality of drugs. - Building materials industry

In the production process of building materials, such as wood drying, asphalt heating, etc., high temperature heating is required for a long time. Due to the high efficiency and energy saving characteristics of the Thermal Oil Boiler, it can significantly improve the heating efficiency and reduce the production cost.

V. How to choose the right Thermal Oil Boiler

There are several key factors to consider when choosing the right Thermal Oil Boiler:

- Heating temperatures and production requirements: Different production processes have different temperature requirements and it is important to select a boiler that offers the right temperature range.

- Boiler capacity: Select the appropriate boiler capacity according to the scale of production to ensure that heating requirements are fully met.

- Thermal efficiency and energy consumption: Focus on the thermal efficiency and energy consumption of the boiler. Choosing an energy efficient model can reduce long term operating costs.

- Safety features of the equipment: Ensure that the boiler complies with the relevant safety standards and is equipped with the necessary safety devices to prevent safety problems caused by high temperatures or overpressure.

so to speak

Thermal Oil Boilers have become indispensable heating equipment in many industries due to their high temperature and low pressure, precise temperature control, high efficiency and energy saving. Whether in the petrochemical high temperature reaction, or in the food, pharmaceutical and other industries in the drying, baking process, Thermal Oil Boilers can provide efficient and safe heating solutions. In the choice of Thermal Oil Boiler, enterprises should be based on their own production needs, choose to meet the performance, safety requirements of the equipment, to ensure the stability and efficiency of the heating process, and thus enhance the overall production efficiency.

The company can be non-standard custom products, click the menu bar can be customised, you can also refer to the first!product pageAppreciate our company's products oh!

Recommended Reading: